Industrial Digital Radiography X Ray Ct Scan

- Aolong

- China

- 15 days

- 80pc/year

1. Industrial CT Scanners Systems' inspection results are extremely accurate, with 3D imaging as precise as a CT scan.

2. Industrial X-ray Inspection Systems is highly automated, resulting in very fast inspection times.

3. Industrial Digital Radiography scan can inspect a wide range of products and operating conditions without changing equipment.

Product Introduction of Industrial X-ray Inspection Systems:

Industrial X-ray Inspection Systems is essentially a set of intelligent equipment that "visualizes" industrial inspection. Industrial X-ray Inspection Systems can clearly present internal structures that are completely invisible to the naked eye using digital methods. Unlike traditional X-rays that can only capture two-dimensional images, Industrial X-ray Inspection Systems can "cut open" the product layer by layer to create a three-dimensional model, clearly showing the structure, cracks, and pores. Industrial Digital Radiography scan is more like performing a physical examination on the product; it's fast, provides stable imaging, and has a high degree of digitalization, making it particularly suitable for manufacturing industries with increasingly stringent quality requirements.

Advantages and Features of Industrial CT Scanners Systems:

Industrial Digital Radiography scan's advantage isn't just "clear images." Its greater strength lies in: imaging complex structures in a single step, without disassembly or cutting, making it completely non-destructive; supporting multiple imaging modes, such as rapid scanning, high-precision local reconstruction, and contrast enhancement, which can be flexibly switched to meet the needs of different products and defect types; coupled with the system's high degree of automation, the entire process from scanning to reconstruction can be completed with a single click, saving engineers both time and effort during inspection. Industrial Digital Radiography scan's data results can be directly synchronized to the quality management system, achieving true data-driven quality control.

Application Scenarios of Industrial Digital Radiography scan:

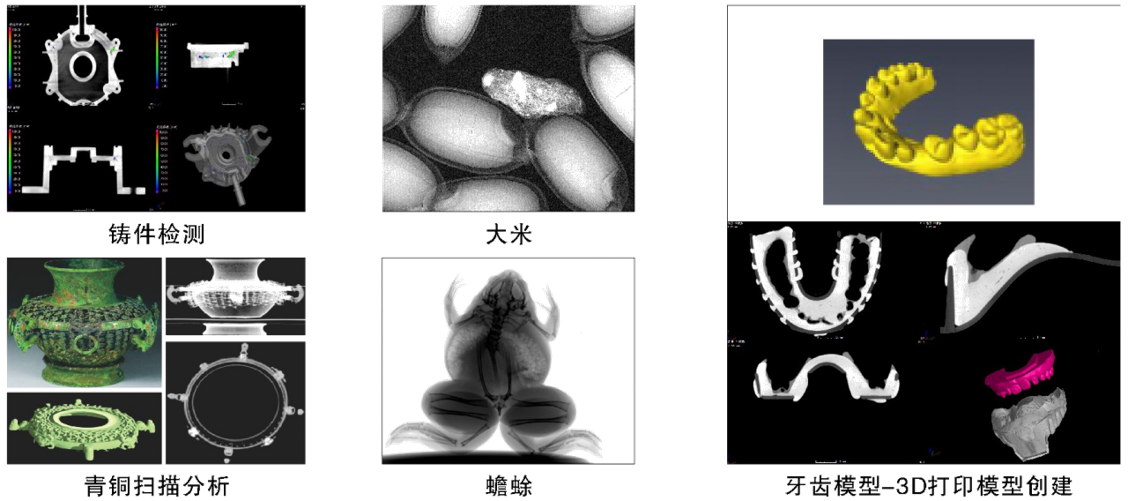

Industrial Digital Radiography X-Ray CT Scans have a wide range of applications; almost any industry that is concerned about internal issues relies on them. For example, they are particularly suitable for batch inspection of common automotive parts such as aluminum alloys, die-cast parts, and welded components; the electronics industry uses them to examine chip packaging and solder joints with exceptional clarity; and the aerospace industry excels at inspecting composite materials and thin-walled structures. Industrial Digital Radiography scan is also increasingly used in the new energy industry, for example, in the production of power batteries, motor magnets, and energy storage components, where Industrial CT Scanners Systems provide both speed and reliability for safety inspections.

Main Functions

● Using cone beam CT scan and DR inspection mode and it can obtainthousands of pieces tomographic images by one time.

● X-ray source suits small objects inspection.

● Industrial CT Scanners Systems can be place on the table.

● lmaging mode: 2D,3D

● The system can analyze defect and pore, support ROl scan.

● Use different color to mark defect's volume, size and position.

● Count and analyze defect dimension, calculating pore ratio, and generatepore volume histogram.

● Analysis of wall thickness: use different color mark the analysis results.

● Measurement tools: measure position,distance,radius angle and otherparameters of the object.

● Reverse engineering: CAD design and compare with physical object.

● Segmentation tool: data centralization, segmentation according to materialand geometry.

● Achieve accurate measurement of internal dimensions of the object.

● Fiber composite material analysis function

● Comparison function between the design and the object

Industrial CT Scanners Systems based on CT technology, supports 2D and 3D inspection and feature automatic defect identification, material analysis, and reverse engineering. Industrial CT Scanners Systems is suitable for inspecting metals, ceramics, cores, complex castings, plastic parts, automotive components, jewelry, new materials, and semiconductors. Industrial CT Scanners Systems are widely used in 3D printing technology, biological research, medicine, aerospace, machinery, electronics, shipbuilding, military, materials science, geology, archaeology, and other fields.

Main Parameters of Industrial X-ray Inspection Systems:

Tube voltage | 20kV~90kV |

| Focus size | 5μm |

| Spatial resolution | 3μm |

| Density resolution | 0.3%~0.5% |

| Scan method | cone beam scanning |

Honors and Certifications:

Aolong Group has been awarded the title of "Liaoning Province Well-known Software Enterprise," fully demonstrating our innovative advantages in the field of testing software and data processing. While developing hardware equipment, the company also emphasizes software algorithm optimization, achieving digitalization and intelligentization of testing. We have undertaken numerous key national scientific research projects with outstanding achievements. The attainment of ISO and CE certifications has enabled our equipment to successfully enter the international market, becoming the designated testing product for important national engineering projects. These honors and certifications comprehensively demonstrate the company's strength.

About Us:

Aolong Group has always adhered to innovation-driven development. Through years of accumulation, it has become a well-known domestic and international supplier of non-destructive testing (NDT) equipment. The company maintains a long-term cooperative relationship with leading international company GE and undertook the NDT tasks for the Shenzhou series manned spacecraft, fully demonstrating its strong technical capabilities. We not only focus on product research and development but also strive to provide customers with complete testing solutions, combined with a comprehensive after-sales service system, to help customers improve testing efficiency and quality.