AI algorithm: revolutionizing the future of industrial X-ray detection technology

With the emergence of Chatgpt, AI has gradually entered the public eye. In recent years, with the rapid development of AI technology, AI algorithms in industrial X-ray detection equipment are becoming an important driving force for industry innovation.

The traditional algorithms of industrial X-ray inspection software mainly rely on manually designed feature extraction and classifiers, which analyze and process images or data obtained in industrial inspection through specific mathematical and statistical methods to achieve defect detection, size measurement, quality evaluation, and other purposes.

Unlike traditional algorithms for data analysis, AI algorithms are capable of capturing data and deep learning. Deep learning algorithms can automatically learn feature representations from large amounts of data without the need for manually designing feature extractors, thus performing well in many complex scenarios. These AI algorithms not only improve the accuracy and efficiency of detection, but also reduce reliance on human experience, making industrial detection more intelligent and automated.

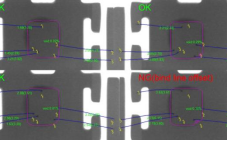

To implement deep learning algorithms, the first step is to have products that continuously accumulate and precipitate X-ray image data in various industrial application fields and detection scenarios. At the same time, with advanced neural network architecture, algorithms are continuously trained, optimized, and iterated to efficiently and accurately recognize targets from complex images, mark their positions and categories, and achieve detection and measurement of defective products, defect types, key product dimensions, etc., achieving high-precision and high-efficiency intelligent detection.

(Defect detection of bonding lines in electronic semiconductor chips)

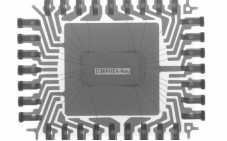

So, the application of AI algorithms in industrial X-ray detection equipment is mainly reflected in two aspects: image reconstruction and data analysis. Firstly, in terms of image reconstruction, AI technology can significantly improve the clarity and processing speed of X-ray scanning images. By training and optimizing the neural network structure, adopting efficient computing devices and algorithms, and utilizing caching and preprocessing techniques, the image processing capability is significantly improved, achieving femtosecond imaging and image clarity restoration.

(Electronic chip X-ray detection imaging image)

Secondly, in terms of data analysis, AI algorithms can achieve intelligent recognition and classification of X-ray images, saving labor costs and reducing misjudgments caused by human factors. By training with a large amount of data, learn the feature information in the image, and automatically recognize and classify the image. For example, in semiconductor packaging inspection, AI algorithms can accurately identify small defects in the packaging, such as cracks, bubbles, etc., providing strong support for product quality control.

(PCBA board bubble rate detection chart)

In the upgrading and iteration of industrial X-ray detection equipment, AI algorithms are leading the future development of detection technology with their unique advantages, safeguarding the production efficiency and product quality of enterprises.