Digital X-ray System For Wheel Inspection

- Aolong

- China

- 15 days

- 300pc/year

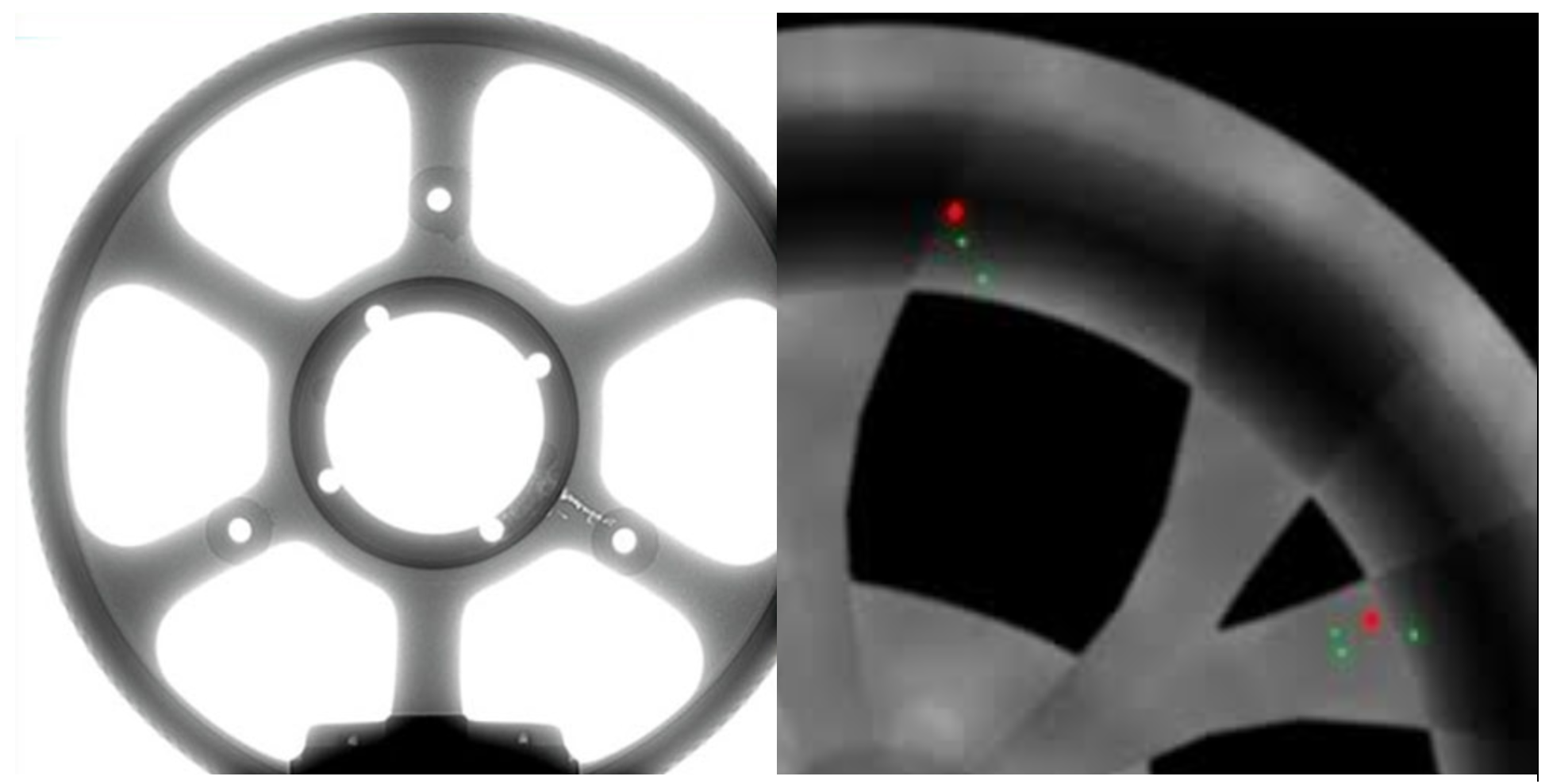

1. Wheel Inspection X-ray system boasts a resolution of 30–36 LP/cm and a sensitivity of 1%–1.8%, clearly revealing internal wheel defects and providing accurate and reliable inspection results.

2. X-ray for Wheel Inspection supports manual, semi-automatic, and fully automatic modes, controlled by a computer and PLC.

3. Wheel hub radiographic inspection system can inspect a variety of wheel sizes, ranging from 13 to 26 inches in diameter, to meet diverse inspection needs.

Product Introduction of Wheel X-ray system Inspection:

Wheel X-ray system Inspection is a high-precision nondestructive testing device designed specifically for automotive wheel quality control. Suitable for inspecting wheels with diameters ranging from 13 inches to 26 inches, X-ray for Wheel Inspection supports manual, semi-automatic, and fully automatic operation modes. With a high-definition resolution of 30–36 LP/cm and a sensitivity of 1%–1.8%, X-ray for Wheel Inspection efficiently and accurately detects internal defects such as cracks, pores, and inclusions. Wheel hub radiographic inspection system utilizes computer and PLC control, and features automatic wheel type recognition and defect analysis, ensuring stable and reliable inspection results.

Digital X-ray System for Wheel Inspection:

| Applicable wheel diameter | 13" - 26" |

| Test speed | ≤ 2 pcs/min (using a 14" wheel as an example) |

| Test mode | Manual / Semi-automatic / Fully Automatic |

| Wheel hub transmission | Automatic wheel type recognition, automatic/semi-automatic defect detection |

| A/D conversion | 16-bit |

| X-ray system resolution | 30 LP/cm - 36 LP/cm |

| X-ray system sensitivity | 1% - 1.8% |

| Control method | Computer + PLC |

| X-ray tube voltage | 30 kV - 160 kV |

| X-ray tube current | 0.5 mA - 5 mA |

| High voltage frequency | 40 kHz |

Wheel Inspection X-ray System Composition

● High-frequency X-ray source

● X-ray flat panel detector

● Computed image processing control system

● Wheel X-ray system Inspection with a transmitting device

● Inspection table

● Lead cabin

Product Applications of Wheel Inspection X-ray system:

Wheel Inspection X-ray system is primarily used for nondestructive testing of automotive wheels, suitable for aluminum alloy wheels, steel wheels, and other cast or forged wheels. X-ray for Wheel Inspection is widely used in automotive manufacturers, wheel production lines, quality control laboratories, and research institutions to detect internal defects such as cracks, shrinkage cavities, air holes, and inclusions, ensuring product compliance with international safety standards.

Automobile OEMs: Wheel X-ray system Inspection performs rigorous quality inspections on wheels before shipment to ensure vehicle safety.

Wheel Manufacturers: Wheel hub radiographic inspection system is used for batch testing on the production line to quickly identify defects in aluminum alloy or steel wheels.

Automotive Parts Suppliers: X-ray for Wheel Inspection ensures product quality throughout the supply chain, ensuring compliance with OEM standards.

Third-Party Testing Agencies: Provide professional wheel testing and certification services.

Research and Laboratories: Used for the development and verification of new wheel materials and processes.

After-Sales Service:

Choosing our Wheel X-ray system Inspection means choosing peace of mind and efficiency. We understand that every hour of downtime can be costly, so we provide rapid response and priority service to help customers resolve emergencies promptly. All new Wheel X-ray system Inspection purchases come with a one-year limited warranty covering parts, labor, travel, and shipping costs, ensuring ultimate peace of mind. Additionally, customers receive unlimited phone support and immediate technical guidance from Wheel Inspection X-ray system.

Inspection Services:

Industrial CT technology is one of our company's core strengths, enabling high-precision 3D imaging and defect analysis of complex components and multi-material products. Whether it's sheet metal like aluminum, iron, or copper, or composite materials and non-metallic products, we can measure and evaluate the microstructure. We also perform metrology testing, assembly error control, and design-to-actual comparison analysis to help clients verify design rationality and process stability. Industrial CT can also be used for reverse engineering, 3D printing modeling, and cultural relic restoration and reconstruction. Our services cover a wide range of fields, including industrial production, scientific research, and cultural heritage preservation.

Our Qualifications:

Aolong has been designated a Liaoning Province Famous Trademark, a high recognition of our brand building and market influence. Over the years, we have upheld the principles of prioritizing quality and service, earning a strong reputation in the field of nondestructive testing with Wheel hub radiographic inspection system ratings. These honors not only demonstrate our customers' trust in Aolong but also demonstrate our strong brand competitiveness, helping us further expand our market, establish long-term and stable development advantages, and continuously enhance our brand value.

FAQs:

Q1: What types of wheels can Wheel Inspection X-ray system inspect?

A1: Wheel Inspection X-ray system is suitable for aluminum alloy wheels, steel wheels, and various sizes (13"–26") manufactured by casting or forging.

Q2: What defects can X-ray for Wheel Inspection detect?

A2: X-ray for Wheel Inspection can accurately identify common defects such as cracks, shrinkage cavities, air holes, and inclusions within wheels.

Q3: What is the Wheel X-ray system Inspection efficiency?

A3: Taking a 14-inch wheel as an example, the Wheel X-ray system Inspection speed is less than 2 pieces per minute, making it suitable for mass production inspection and quality control.

Q4: Does Wheel hub radiographic inspection system comply with international standards?

A4: X-ray for Wheel Inspection utilizes computer and PLC control, coupled with high-definition resolution and high sensitivity, to meet the stringent quality and safety testing standards of the automotive industry.

About Us:

Aolong boasts a modern manufacturing facility and testing laboratory, strictly adhering to internationally standardized quality management systems. Each unit undergoes numerous performance tests and safety assessments before shipment to ensure reliability and stability. Aolong prioritizes comprehensive quality control, from component procurement to complete unit delivery. With high standards of management and Wheel Inspection X-ray system certification, Aolong has earned the trust of its customers and established long-term, stable partnerships.