XXG-3005 Directional X-ray Flaw Detector

- Aolong

- China

- 15 days

- 1500pc/

1. The XXG-3005 x-ray flaw detector is equipped with a 300kV ceramic X-ray tube, ensuring stable and reliable high-energy output.

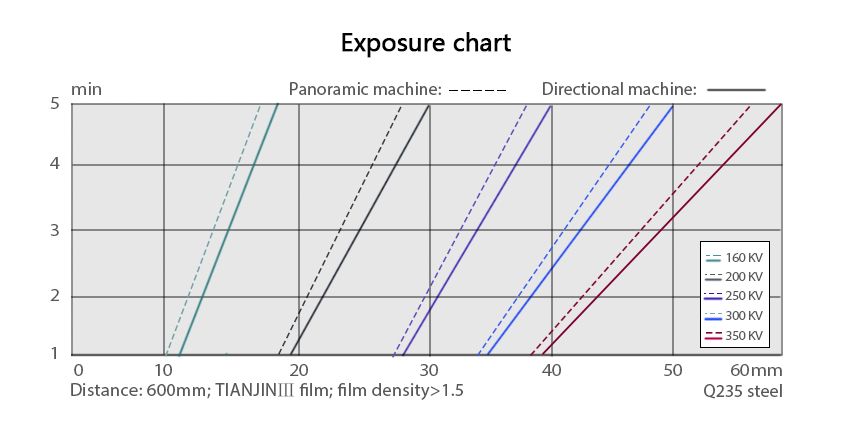

2. At a 300kV operating voltage and a 600mm focal length, Aolong's XXG-3005 Panoramic X-ray Flaw Detector can clearly penetrate 50mm thick Q235 steel, placing it at the forefront of similar equipment in China.

3. The XXG-3005 Panoramic X-ray Flaw Detector utilizes an optimized 40+5° radiation angle design, ensuring a wide detection range while minimizing scattering interference.

Product Description of XXG-3005 Panoramic X-ray Flaw Detector:

The XXG-3005 Panoramic X-ray Flaw Detector is a fifth-generation portable directional X-ray flaw detector with a rated voltage of 300 kV, primarily used to detect internal defects in metal materials and welded structures. Utilizing directional radiation technology, the XXG 3005 Industrial Portable Detector emits X-rays at a 160° cone angle, enabling efficient inspection of large workpieces such as boilers, pressure vessels, oil and gas pipelines, and ship structures. The XXG 3005 Industrial Portable Detector's high-voltage coil utilizes imported German enameled wire, fundamentally resolving the low reliability issues associated with traditional high-voltage coils. Combined with directional exposure technology, the system ensures image quality while minimizing radiation exposure.

Features of XXG-3005 Panoramic X-ray Flaw Detector:

| Function Name of XXG-3005 x-ray flaw detector | Functional Description of XXG 3005 Industrial Portable Detector |

| System Self-Diagnosis of XXG-3005 x-ray flaw detector | Upon startup, the XXG 3005 Industrial Portable Detector automatically performs a self-test of its software and hardware systems to ensure normal initial operation. |

| Field Operation Capability of XXG-3005 x-ray flaw detector | It features excellent anti-interference performance and supports motor drive, making XXG-3005 Panoramic X-ray Flaw Detector suitable for field operations without a mains power supply. |

| Key Parameter Adjustment of Directional x-ray flaw detector | Exposure parameters can be adjusted directly via the device's buttons, making operation simple and intuitive. |

| High-Voltage Delay Start | A delayed high-voltage start function allows operators time to exit hazardous areas. |

| High-Voltage Slow-Ramp Function | The high-voltage ramp-up function adjusts slowly, effectively protecting the X-ray tube of Directional x-ray flaw detector from transient current surges. |

| 1:1 Intermittent Operation | XXG-3005 x-ray flaw detector features an automatic 1:1 duty cycle control with a maximum continuous exposure time of 5 minutes to prevent overheating. |

| Multiple Safety Protections | XXG-3005 x-ray flaw detector features a comprehensive protection system, including overvoltage, undercurrent, overcurrent, and overtemperature protection, as well as audible and visual alarms. |

| Easy Maintenance of XXG-3005 Panoramic X-ray Flaw Detector | The modular design of XXG-3005 x-ray flaw detector allows for easy maintenance, reducing the difficulty and cost of future maintenance. |

| Local Operation Optimization of XXG 3005 Industrial Portable Detector | The robust design is optimized for local operation, making it even more convenient to use. |

| Time Compensation | Exposure time can be adjusted to ±0.3° based on power grid conditions, ensuring more precise exposure. |

R&D Improvements of Directional x-ray flaw detector:

After the development of the Directional x-ray flaw detector, frequent quality issues with the high-voltage coil persisted, a problem that remained unresolved. Through continuous research, Aolong engineers finally identified the cause: uneven diameters of the enameled wire used in the coils, leading to damage. After repeated testing of the Directional x-ray flaw detector and the use of imported German enameled wire, the high-voltage coil quality issues were resolved, ensuring the overall operational quality of the Directional x-ray flaw detector.

XXG-3005 x-ray flaw detector's structural components:

The XXG-3005 x-ray flaw detector's high-voltage generator system, the core of the equipment, utilizes a high-performance 300kV ceramic X-ray tube. High-voltage coils are precision-wound with special enameled wire imported from Germany, maintaining optimal operating temperatures during operation.

The XXG 3005 Industrial Portable Detector's control system utilizes an innovative modular architecture, comprised of four independent functional boards working together. The control system housing is constructed of high-strength engineering plastic and features an IP54-rated operation panel.

The XXG 3005 Industrial Portable Detector's supporting structure utilizes aircraft-grade aluminum alloy for its main frame. The adjustable bracket base allows for quick assembly and disassembly of the interface mechanism, making the Directional x-ray flaw detector extremely easy to operate.

The Directional x-ray flaw detector's safety system integrates multiple protection mechanisms, including precise radiation angle limits, intelligent overvoltage and overcurrent protection modules, and real-time temperature monitoring.

Specifications

Panoramic Portable X-ray Flaw Detector (with ceramic X-ray tube)

| Model | Output Voltage (kv) | Input (kw) | Focus (mm) | Beam Angle | Q235 Max. Penetration(mm) | Weight of Generator(kg) | Dimension of Generator(mm) | ||

| Cone Target | Flat Target | Cone Target | Flat Target | ||||||

| XXGH-2005 | 100~200 | 2.0 | 1.0×3.5 | 30×360° | 25×360° | 24 | 27 | 31 | 290×615 |

| XXGH-2505 | 150~250 | 2.5 | 1.0×2.4 | 30×360° | 25×360° | 34 | 37 | 35 | 325×705 |

| XXGH-3005 | 170~300 | 3.0 | 1.0×2.3 | 30×360° | 25×360° | 44 | 47 | 43 | 245×715 |

Panoramic Portable X-ray Flaw Detector (with glass X-ray tube)

| Model | Output Voltage (kV) | Input (kw) | Focus Size (mm) | Beam Angle | Q235 Max. Penetration(mm) | Weight of Generator(kg) | Dimension of Generator(mm) | ||

| Cone Target | Flat Target | Cone Target | Flat Target | ||||||

| XXH-1005 | 60~100 | 1.2 | 1.0×3.5 | 30×360° | 25×360° | 4 | 6 | 11.1 | 190×530 |

| XXH-1605 | 80~160 | 1.5 | 1.0×3.5 | 30×360° | 25×360° | 12 | 15 | 15 | 225×585 |

| XXH-2005 | 100~200 | 2.0 | 1.0×3.5 | 30×360° | 25×360° | 24 | 27 | 21.5 | 285×665 |

| XXH-2505 | 150~250 | 2.5 | 1.0×2.4 | 30×360° | 25×360° | 34 | 37 | 33.5 | 320×730 |

| XXH-3005 | 170~300 | 3.0 | 1.0×2.3 | 30×360° | 25×360° | 44 | 47 | 40 | 345×830 |

| XXH-3205 | 180~320 | 3.2 | 1.0×5.0 | 30×360° | 25×360° | 45 | 50 | 40 | 345×830 |

| XXH-3505 | 180~350 | 3.4 | 1.0×5.0 | 30×360° | 25×360° | 52 | 55 | 42.6 | 345×830 |

Directional Portable X-ray Flaw Detector (with glass X-ray tube)

| Model | Output Voltage (kV) | Input (kw) | Focus Size (mm) | Beam Angle | Q235 Max. Penetration(mm) | Weight of Generator(kg) | Dimension of Generator(mm) |

| XXQ-1005 | 60~100 | 1.2 | 0.8×0.8 | 40° | 8 | 11.1 | 190×530 |

| XXQ-1605 | 80~160 | 1.5 | 0.8×0.8 | 40° | 19 | 15.2 | 225×585 |

| XXQ-2050 | 100~200 | 2.0 | 1.5×1.5 | 40+5° | 30 | 23 | 285×665 |

| XXQ-2505 | 150~250 | 2.5 | 2.0×2.0 | 40+5° | 40 | 35 | 320×730 |

| XXQ-3005 | 170~300 | 3.0 | 2.3×2.3 | 40+5° | 50 | 45.5 | 345×830 |

| XXQ-3205 | 180~320 | 3.2 | 2.5×2.3 | 40+5° | 55 | 45.5 | 345×830 |

| XXQ-3505 | 180~350 | 3.4 | 2.8×3.0 | 40+5° | 60 | 47 | 345×800 |

Directional Portable X-ray Flaw Detector (with ceramic X-ray tube)

| Model | Output Voltage (kV) | Input (kw) | Focus Size (mm) | Beam Angle | Q235 Max. Penetration(mm) | Weight of Generator(kg) | Dimension of Generator(mm) |

| XXG-1605 | 80~160 | 1.5 | 0.8×0.8 | 40+5° | 19 | 14.5 | 225×550 |

| XXG-2005 | 100~200 | 2.0 | 2.0×2.0 | 40+5° | 30 | 18 | 285×615 |

| XXG-2505 | 150~250 | 2.5 | 2.0×2.0 | 40+5° | 40 | 30.5 | 320×640 |

| XXG-3005 | 170~300 | 3.0 | 2.5×2.5 | 40+5° | 50 | 36.5 | 345×670 |

| XXG-3505 | 180~350 | 3.5 | 2.5×2.5 | 40+5° | 60 | 38 | 345×670 |

Honors and Qualifications:

Thanks to its outstanding performance in the industry, Aolong Group has been awarded numerous honorary titles, including "National High-Tech Enterprise" and "Famous Trademark of Liaoning Province." The company's independently developed digital microfocus X-ray inspection system has been recognized as a national high-tech industrialization demonstration project, demonstrating its technological advancement and reliability. Furthermore, as the "National Digital X-ray System Industrialization Demonstration Project Center," we shoulder the important mission of promoting technological standardization and industrial upgrading. These qualifications and honors fully demonstrate Aolong Group's authoritative position in the industry.

About Us:

Aolong's digital inspection system supports cloud-based data management and intelligent analysis, integrating with customers' MES or ERP systems to achieve quality traceability throughout the entire production process. Through big data analysis and intelligent interpretation, customers can quickly identify process issues and implement optimizations. Aolong helps customers establish a complete closed-loop quality management system, from incoming material inspection to finished product testing, significantly improving production efficiency and quality control while reducing the risk of defects.