XXQ-2005 X-ray Destructive Testing Of Welds Instrment

- Aolong

- China

- 15 days

- 1500pc/year

XXQ-2005 X-ray Destructive Testing Of Welds Instrment equipped with the seletcted 200 kV glass X-ray insert with the beam angle of 40+5°. Under the working voltage of 200kV and focal distance of 600mm, it can penetrate 30mm Q235 steel, which is the higher level of similar machine in China.

XXQ-2005 x-ray Non Destructive Testing of Welds instrment equipped with the seletcted 160 kV ceramic X-ray insert with the beam angle of 40+5°. Under the working voltage of 160kV and focal distance of 600mm, it can penetrate 19mm Q235 steel, which is the highest level of similar machine in China.

XXQ-2005 X-ray Destructive Testing Of Welds Instrment uses the X-ray radiography.

X-ray radiography can intuitively show the size and shape of defects inside the workpiece, so it is easy to judge the nature of defects. X-ray film can be used as the original record of inspection for multi-party research and long-term preservation, and has high sensitivity for nondestructive flaw detection of thin-walled workpiece.Sensitive to volumetric defects, defect image of the plane distribution of true, dimensional measurement.There are no strict requirements on the surface finish of the workpiece, and the grain size of the material has little influence on the detection result. It can be applied to the detection of internal defects of various materials, so it is widely used in the welding quality inspection of pressure vessels.

Using radiographic testing method, the portable X-ray flaw detector is used for the internal defects and welding test of the work piece via the images on the X-ray film in order to evaluate the quality of the products. It is suitable for X ray NDT detection of materials like thin iron plate, aluminum, rubber etc.

CONTROLLER

The control panel is suitable for all series of the XXQ-2005 x-ray instrument.

The volume of the control panel is 270 ×270× 140mm, weight less than 10kg, very convenient to carry, easy to use in the field.

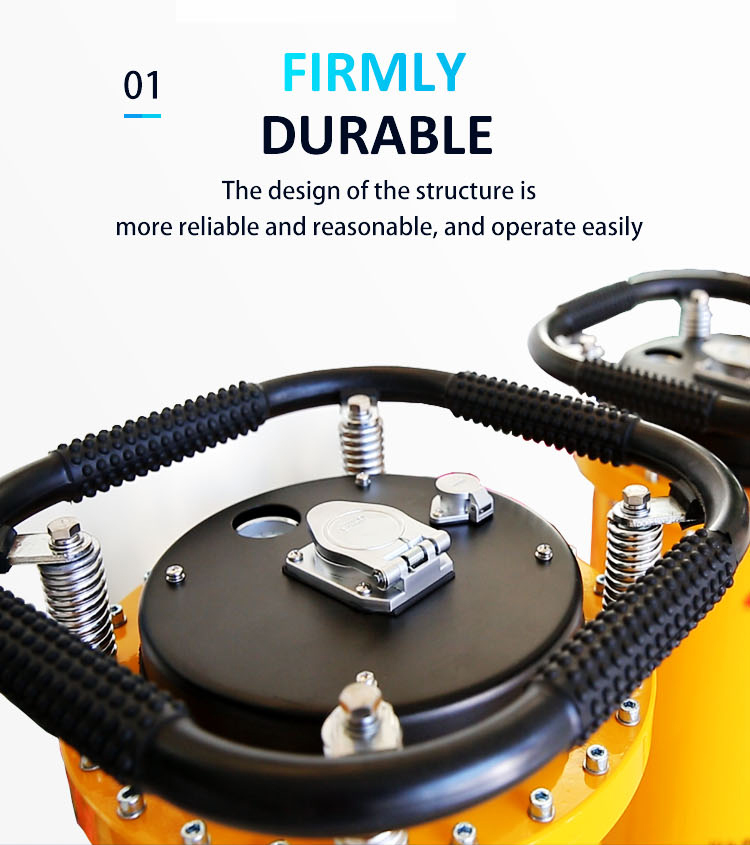

SOLID AND DURABLE STRUCTURAL DESIGN

The generator of the XXQ-2005 X-ray Destructive Testing Of Welds Instrment is protected by end rings, solid steel over 15 mm is selected, and rubber is wrapped outside to prevent slipping. The end rings can prevent the core parts from being damaged in case of collision. Low voltage cable with low temperature resistance can ensure normal operation at - 30 ℃.

SPECIFICATIONS

Panoramic Portable X-ray Flaw Detector (with ceramic X-ray tube)

| Model | Output Voltage (kv) | Input (kw) | Focus (mm) | Beam Angle | Q235 Max. Penetration(mm) | Weight of Generator(kg) | Dimension of Generator(mm) | ||

| Cone Target | Flat Target | Cone Target | Flat Target | ||||||

| XXGH-2005 | 100~200 | 2.0 | 1.0×3.5 | 30×360° | 25×360° | 24 | 27 | 31 | 290×615 |

| XXGH-2505 | 150~250 | 2.5 | 1.0×2.4 | 30×360° | 25×360° | 34 | 37 | 35 | 325×705 |

| XXGH-3005 | 170~300 | 3.0 | 1.0×2.3 | 30×360° | 25×360° | 44 | 47 | 43 | 245×715 |

Panoramic Portable X-ray Flaw Detector (with glass X-ray tube)

| Model | Output Voltage (kV) | Input (kw) | Focus Size (mm) | Beam Angle | Q235 Max. Penetration(mm) | Weight of Generator(kg) | Dimension of Generator(mm) | ||

| Cone Target | Flat Target | Cone Target | Flat Target | ||||||

| XXH-1005 | 60~100 | 1.2 | 1.0×3.5 | 30×360° | 25×360° | 4 | 6 | 11.1 | 190×530 |

| XXH-1605 | 80~160 | 1.5 | 1.0×3.5 | 30×360° | 25×360° | 12 | 15 | 15 | 225×585 |

| XXH-2005 | 100~200 | 2.0 | 1.0×3.5 | 30×360° | 25×360° | 24 | 27 | 21.5 | 285×665 |

| XXH-2505 | 150~250 | 2.5 | 1.0×2.4 | 30×360° | 25×360° | 34 | 37 | 33.5 | 320×730 |

| XXH-3005 | 170~300 | 3.0 | 1.0×2.3 | 30×360° | 25×360° | 44 | 47 | 40 | 345×830 |

| XXH-3205 | 180~320 | 3.2 | 1.0×5.0 | 30×360° | 25×360° | 45 | 50 | 40 | 345×830 |

| XXH-3505 | 180~350 | 3.4 | 1.0×5.0 | 30×360° | 25×360° | 52 | 55 | 42.6 | 345×830 |

Directional Portable X-ray Flaw Detector (with glass X-ray tube)

| Model | Output Voltage (kV) | Input (kw) | Focus Size (mm) | Beam Angle | Q235 Max. Penetration(mm) | Weight of Generator(kg) | Dimension of Generator(mm) |

| XXQ-1005 | 60~100 | 1.2 | 0.8×0.8 | 40° | 8 | 11.1 | 190×530 |

| XXQ-1605 | 80~160 | 1.5 | 0.8×0.8 | 40° | 19 | 15.2 | 225×585 |

| XXQ-2050 | 100~200 | 2.0 | 1.5×1.5 | 40+5° | 30 | 23 | 285×665 |

| XXQ-2505 | 150~250 | 2.5 | 2.0×2.0 | 40+5° | 40 | 35 | 320×730 |

| XXQ-3005 | 170~300 | 3.0 | 2.3×2.3 | 40+5° | 50 | 45.5 | 345×830 |

| XXQ-3205 | 180~320 | 3.2 | 2.5×2.3 | 40+5° | 55 | 45.5 | 345×830 |

| XXQ-3505 | 180~350 | 3.4 | 2.8×3.0 | 40+5° | 60 | 47 | 345×800 |

Directional Portable X-ray Flaw Detector (with ceramic X-ray tube)

| Model | Output Voltage (kV) | Input (kw) | Focus Size (mm) | Beam Angle | Q235 Max. Penetration(mm) | Weight of Generator(kg) | Dimension of Generator(mm) |

| XXG-1605 | 80~160 | 1.5 | 0.8×0.8 | 40+5° | 19 | 14.5 | 225×550 |

| XXG-2005 | 100~200 | 2.0 | 2.0×2.0 | 40+5° | 30 | 18 | 285×615 |

| XXG-2505 | 150~250 | 2.5 | 2.0×2.0 | 40+5° | 40 | 30.5 | 320×640 |

| XXG-3005 | 170~300 | 3.0 | 2.5×2.5 | 40+5° | 50 | 36.5 | 345×670 |

| XXG-3505 | 180~350 | 3.5 | 2.5×2.5 | 40+5° | 60 | 38 | 345×670 |

XXG-2005 Portable X-ray Flaw Detector

Packing details

Each product will be packed in cartons or wooden cases (we also accept customers' demands)

Delivery time

1. For sample order, 3-5 working days

2. For mass production, 5-7 weeks (It also depends on the order quantity and design)