Integrated Lightweight Die Casting Inspection

- Aolong

- China

- 15 days

- 80pc/year

1. X-ray pcb inspection system utilizes advanced X-ray digital imaging technology to clearly reveal even tiny defects within lightweight castings.

2. X-ray pcb inspection system enables real-time online testing, identifying problems promptly and reducing the risk of batch scrapping.

3. X-ray pcb inspection system features a built-in automatic defect recognition algorithm and data traceability capabilities, improving inspection efficiency.

Product Description of x-ray inspection system:

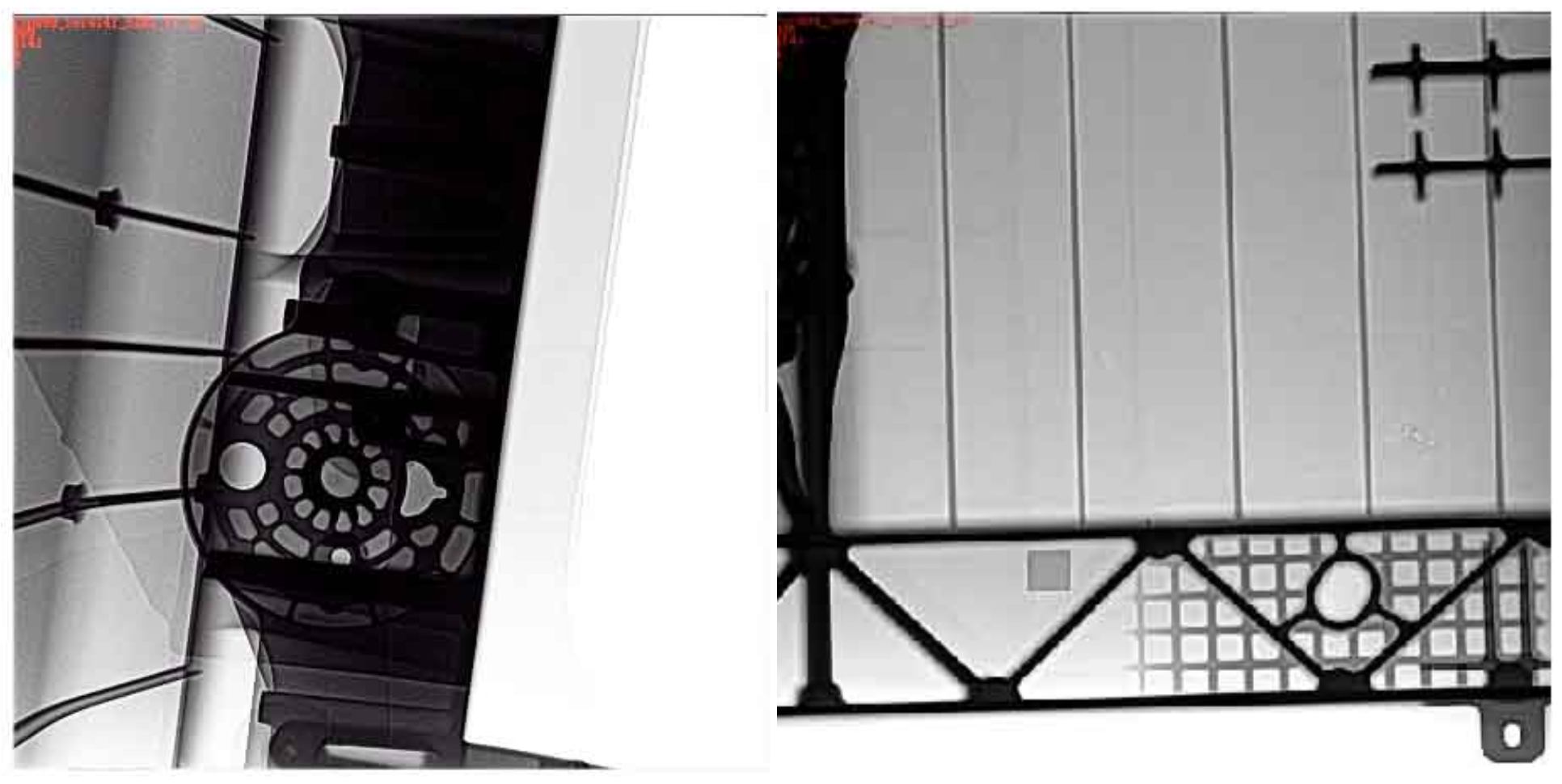

The Integrated Lightweight Die Casting Inspection is a high-end digital inspection system designed specifically for lightweight casting inspection. Combining advanced X-ray imaging and intelligent analysis technologies, Automatic Die Cast Inspection Machine enables non-destructive testing of complex structural components made of lightweight materials such as aluminum and magnesium alloys, quickly identifying internal defects such as porosity, cracks, shrinkage, and inclusions. Automatic Die Cast Inspection Machine supports high-resolution real-time imaging and can be integrated with customers' production lines, enabling real-time quality control throughout the production process for the automotive, new energy, and aerospace industries, ensuring the safety and reliability of lightweight components. X-ray inspection system's automated inspection and intelligent data analysis significantly reduce labor costs, improve inspection efficiency and consistency, and provide customers with more efficient and accurate quality management solutions.

Product Applications of x-ray inspection system:

Integrated Lightweight Die Casting Inspection (ILDI) is widely used in industries with stringent requirements for lightweight castings, such as new energy vehicles, aerospace, and precision machinery manufacturing. x-ray inspection system enables real-time inspection of complex thin-walled structural parts, such as aluminum and magnesium alloys, during the production process. It can promptly identify potential defects such as internal porosity, shrinkage, or cracks, ensuring consistent and reliable part quality before mass assembly. In the new energy vehicle sector, x-ray inspection system can be used to inspect key components such as motor housings and battery trays. In the aerospace sector, pcb inspection system is suitable for quality control of engine structural parts and fuselage connectors. Through pcb inspection system's non-destructive testing and intelligent analysis capabilities, customers can significantly reduce scrap and rework costs while significantly improving overall production efficiency and product reliability.

Automatic Die Cast Inspection Machine's High-Precision Nondestructive Testing:

Integrated Lightweight Die Casting Inspection (ILDI) achieves high-precision nondestructive testing by combining advanced digital X-ray imaging technology with a microfocus X-ray source. Using a high-resolution flat-panel detector, Automatic Die Cast Inspection Machine captures clear images of the interior of castings, magnifying and capturing even the smallest defects such as pores, shrinkage, and cracks in lightweight materials such as aluminum and magnesium alloys. X-ray PCB inspection system's intelligent image processing and automatic recognition algorithms enable precise analysis of complex structures, eliminating human errors. The entire inspection process requires no sample damage or cutting, enabling comprehensive inspections to be completed in a short period of time.

FAQs of x-ray pcb inspection system:

1. Why do lightweight castings require specialized inspection systems?

Although lightweight castings (such as aluminum and magnesium alloys) are lightweight, they are prone to internal defects such as porosity and shrinkage during the production process, which are difficult to detect using conventional inspection methods. Integrated Lightweight Die Casting Inspection uses high-resolution X-ray imaging to detect subtle defects without damaging the part, ensuring component safety and reliability.

2. Can X-ray PCB inspection system meet the inspection needs of complex structural parts?

x-ray pcb inspection system utilizes a microfocus X-ray source and intelligent analysis algorithms to achieve high-definition imaging and accurate analysis, even for complex structural parts with thin walls, multiple curved surfaces, or multiple cavities, regardless of part geometry.

3. Does X-ray inspection system support subsequent data traceability and process improvement?

The X-ray inspection system provides inspection data storage, comparison, and traceability capabilities. Companies can use this data for failure analysis and process optimization, continuously improving production processes and enhancing the consistency and reliability of castings.

After-Sales Service and Support:

Our support system goes beyond maintenance services; it extends our comprehensive value proposition. Through customized support plans, customers can maximize x-ray inspection system's uptime and avoid unnecessary production interruptions. Furthermore, a combination of systematic initial training and ongoing maintenance keeps Automatic Die Cast Inspection Machine in top condition, ensuring continuous production. By partnering with us, customers receive more than just x-ray inspection system; they receive a complete, reliable operational support solution.

Honorary Qualifications:

Aolong products are CE certified, complying with EU market safety, health, and environmental requirements. This certification signifies that our Automatic Die Cast Inspection Machine products have gained access to the international market and are eligible for export to Europe and other regions. Through rigorous testing and auditing, X-ray PCB inspection system products meet standards in radiation protection, electromagnetic compatibility, and other areas. This certification provides customers with greater confidence during purchase and use, and provides a solid foundation for the company's international expansion.

About Us:

Our company prioritizes technological innovation, developing a comprehensive technology pipeline encompassing microfocus X-ray sources, digital detectors, and imaging algorithms. Our R&D team, comprised of PhDs, Masters, and senior engineers, possesses extensive experience and interdisciplinary capabilities. Through continuous R&D investment, Aolong's products continuously enhance image clarity, inspection efficiency, and intelligence, meeting customer needs across diverse production processes and solidifying our leading position in the industry.