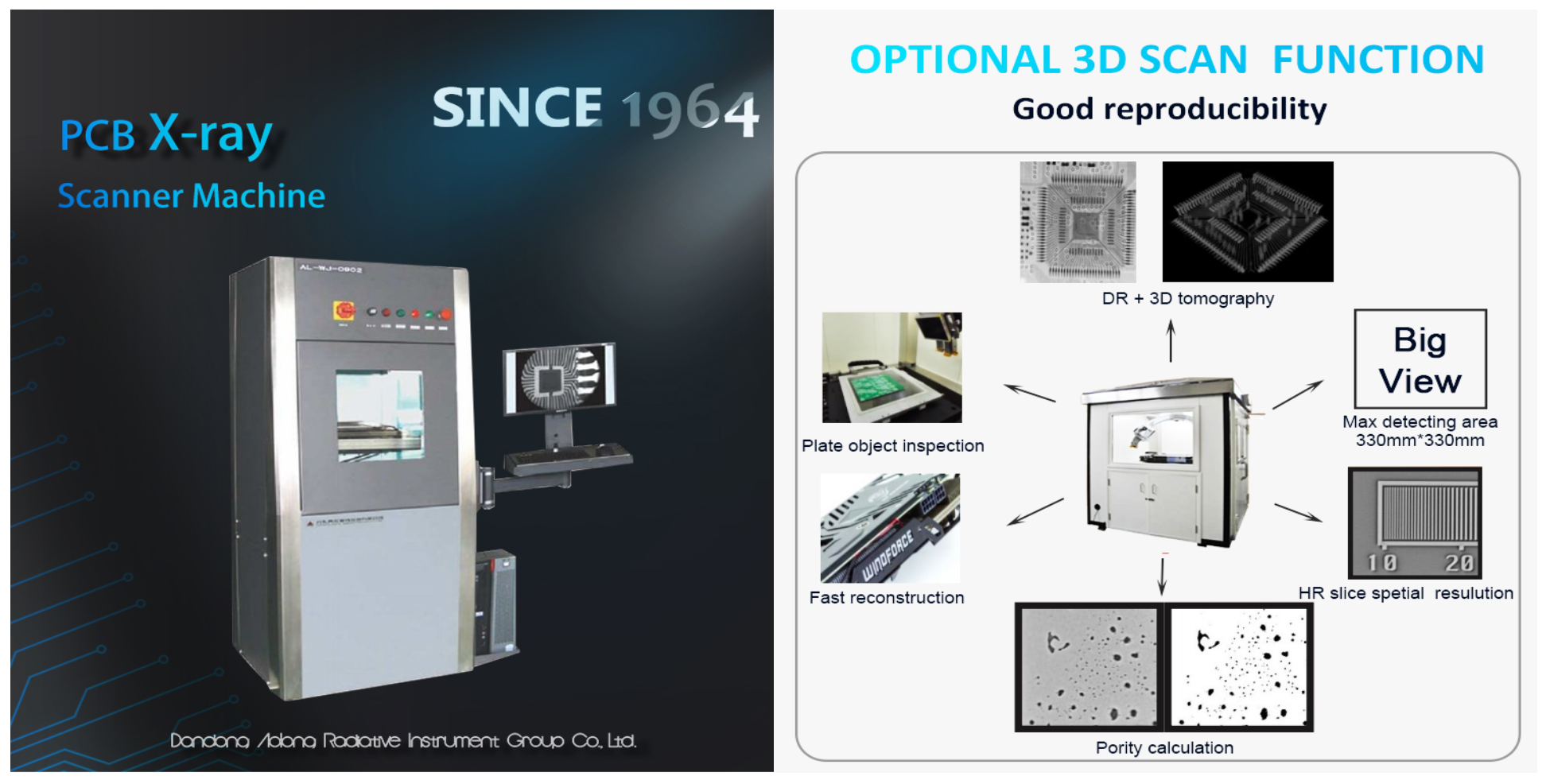

Pcb X Ray Scanner Machine

- Aolong

- China

- 15 days

- 80pc/year

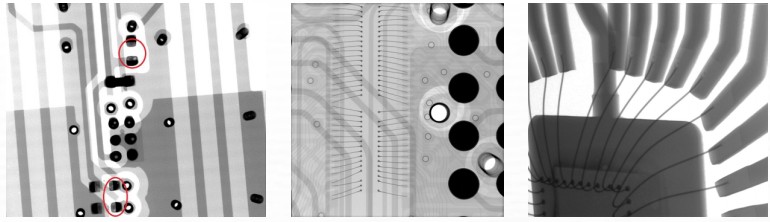

1. Pcb scanner machine utilizes a microfocus X-ray source and a high-resolution flat-panel detector, enabling clear visualization of tiny solder joints, the internal structures of BGAs, QFNs, and other components, as well as hidden defects.

2. Pcb scanner machine enables non-destructive testing.

3. Pcb scanner machine's built-in intelligent recognition algorithm automatically identifies casting defects.

Product Introduction of X ray scanner machine:

X ray scanner machine is an industrial inspection device that primarily utilizes the penetrating properties of X-rays to perform non-destructive X-ray imaging of circuit boards. X ray scanner machine can clearly visualize structures invisible to the naked eye, such as the interior of component packages (such as BGA solder balls), traces within multilayer boards, and solder joint connections. Metal X-ray Inspection system is used to precisely locate defects such as cold solder joints, bridging, and voids, making it a critical tool for ensuring PCB manufacturing quality and conducting failure analysis.

Product Advantages of Metal X-ray Inspection system:

1. Metal X-ray Inspection system supports 2D perspective, 360° rotation, and tilt imaging, making it suitable for comprehensive inspection of multi-layer boards and complex packages.

2. Metal X-ray Inspection system's user-friendly interface and intelligent software make it easy to use after basic training, reducing the need for specialized inspection personnel.

3. X ray scanner machine supports storage of inspection results, report generation, and historical data comparison, facilitating quality traceability and process optimization.

4. X ray scanner machine is suitable for SMT factories, EMS foundries, semiconductor companies, and various high-precision electronics manufacturing industries.

PCB X ray machine's Multi-Angle Imaging:

Pcb x ray machine features flexible multi-angle viewing capabilities, enabling 2D perspective imaging, 360° rotation, and multi-angle tilting, allowing inspectors to easily obtain high-definition images of the PCB's interior from different angles. For complex packaging structures like multi-layer boards, BGAs, and QFNs, traditional single-angle imaging often fails to fully capture internal details. Pcb x ray machine's multi-angle imaging effectively avoids blind spots and helps quickly locate defects such as voids, cold solder joints, and bridging.

Industry Applications of pcb scanner machine:

PCB scanner machine plays a critical role in multiple industries. In the automotive electronics industry, pcb scanner machine can inspect the weld quality of power battery management systems, sensors, and ECU control units, ensuring driving safety and stability. In communications equipment manufacturing, pcb scanner machine helps verify the complex multi-layer boards of base stations, routers, and 5G modules, ensuring stable signal transmission. In the medical electronics field, pcb x ray machine is widely used to inspect the quality of high-reliability devices such as pacemakers and medical monitoring equipment, preventing potential safety issues.

Main Functions of Image Processing System:

● Pcb x ray machine with virtual 3D imaging, real-time imaging zoom in and out.

● Gray level optimized, real-time artificial, humanized design

● Electronic shoot, many frames superposition, fast and convenie

● Supporting positive and negative imaging, edge strength

● The pcb x ray machine with precise measurement of the curve and statistics

● The Radiography x-ray system with BGA welds measurement technology

● Measuring the angles,radius, welding ball area, air pore; pore proportion calculating and welding ball coordinate and statistic

● Dynamic store, print, DVD read and write and other output mode

Main Parameters of x ray scanner machine:

| Tube voltage range | 20kV~160kV |

| Tube current range | 0.1μA~1000μA |

| JIMA Resolution | 0.5μm~2μm |

| Magnification | 20 times~3000 times |

| X ray scanner machine | |

| The inspect platform can move along x,y and z axes | |

FAQs of pcb x ray machine:

1. Can the pcb x ray machine detect hidden defects under BGA or CSP packages?

The pcb x ray machine's X-rays can penetrate packaging materials, clearly revealing the quality of the solder joints on the underside of components like BGAs and CSPs.

2. What is the pcb x ray machine's inspection resolution?

The resolution varies between different Metal X-ray Inspection system models, generally ranging from 0.5μm to 2μm, enabling accurate detection of minute defects in high-density PCBs.

3. Is the Metal X-ray Inspection system safe for operators and products during use?

The pcb scanner machine is designed with radiation shielding that complies with international safety standards. Its radiation dose is very low, making it safe for both operators and electronic components.

4. Can the x ray scanner machine be integrated with an SMT production line?

Yes. In addition to standalone pcb scanner machine models for labs and R&D, we also offer an in-line automated X-ray inspection system (AXI) that can be directly integrated into SMT production lines for real-time quality inspection.

Production Capacity of PCB X ray machine:

To help customers achieve long-term, stable production goals, our service plan covers the entire x ray scanner machine process, from delivery, training, maintenance, and repair. PCB scanner machine system updates and training further optimize performance, empowering operations teams to perform their daily tasks with greater ease. Through our comprehensive service system, customers not only enjoy a highly efficient pcb scanner machine experience, but also gain tangible advantages in management and cost control.

About us:

The company's designation as a Liaoning Provincial Enterprise Technology Center demonstrates Aolong's significant role in technology research and development within the regional industrial innovation system. By pooling scientific research resources and talent, the company has driven breakthroughs in core technologies such as Metal X-ray Inspection system, digital detectors, and image algorithms, achieving widespread influence.