XXQ-1005 Glass X-ray Tube Inspection Equipment

- Aolong

- China

- 15 days

- 1500pc/year

1. Our XXQ-1005 glass x-ray tube equipment is equipped with a 160kV ceramic X-ray tube, which adopts a small focus design, which can capture subtle damage inside the glass and ensure accurate and reliable test results.

2. Our XXQ-1005 glass x-ray tube equipment can easily penetrate glass, which can meet the inspection needs of glass and glass composite components, and its penetration is at the leading level in the same type of XXQ-1005 glass x-ray equipment.

3. Our XXQ-1005 glass x-ray tube equipment is equipped with additional auxiliary radiation angle to improve the flexibility of on-site operation, and can be adapted to glass workpieces of different sizes and shapes. There is no need to adjust the glass x-ray tube inspection equipment position frequently to reduce the difficulty of operation.

XXQ-1005 glass x-ray tube equipment introduction:

Our XXQ-1005 glass x-ray tube equipment is a non-destructive testing equipment specially developed for the glass industry. Through innovative X-ray imaging technology, glass x-ray tube inspection equipment can detect invisible defects such as bubbles, microcracks, impurities and stress distribution inside glass products. Our XXQ-1005 glass x-ray equipment uses a modular design and is equipped with an intelligent protection system, which can meet the needs of precision laboratory testing and adapt to the continuous operating environment of the production line.

Advantages of XXQ-1005 glass x-ray tube equipment:

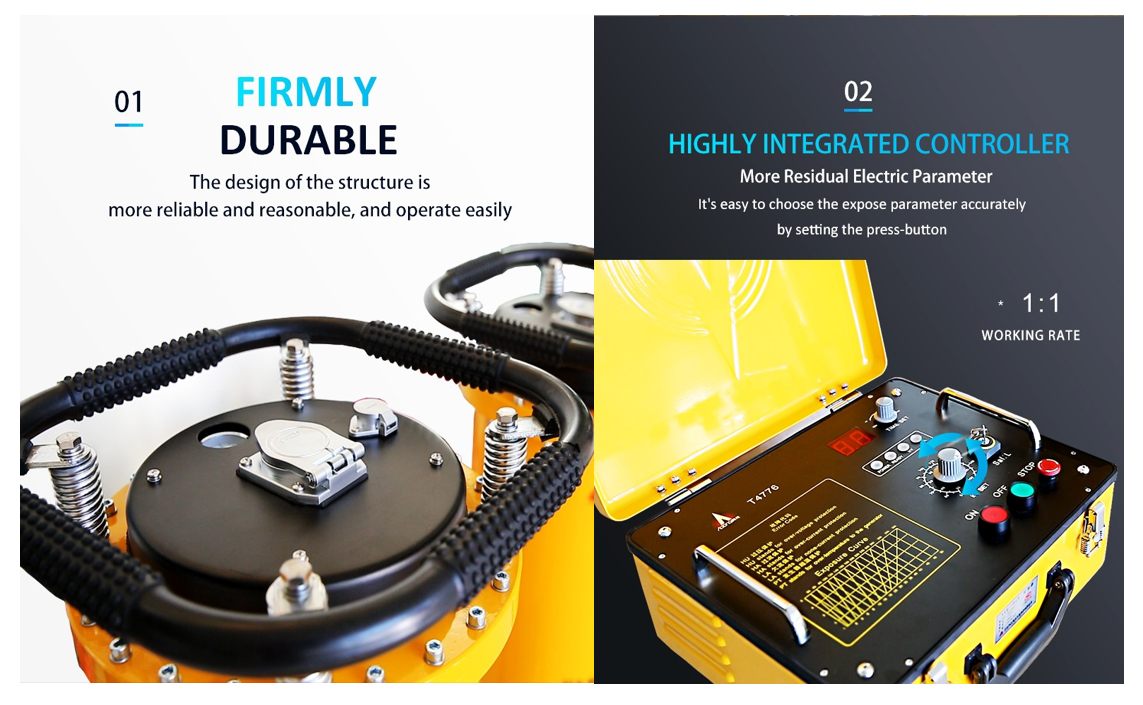

Long service life: Stable XXQ-1005 glass x-ray tube equipment has undergone rigorous quality inspection, and glass x-ray tube inspection equipment adopts durable materials and stable structure as a whole to reduce component losses, extend the overall service life of glass x-ray tube inspection equipment, and reduce long-term use costs.

Small size and light weight: Glass X-ray tube inspection machine is compact and light in weight, which is convenient for on-site movement, installation and storage, and is suitable for a variety of inspection scenarios.

Excellent reliability and stability: Glass X-ray tube inspection machine will carry out continuous operation testing and performance calibration before leaving the factory, and the XXQ-1005 glass x-ray equipment parameters are stable during operation, which can stably meet the testing needs for a long time.

Low failure rate: from raw material procurement to production processes are strictly controlled, the quality of core components is guaranteed, failures caused by component problems are reduced, and the frequency of XXQ-1005 glass x-ray equipment downtime and maintenance is reduced.

How glass x-ray tube inspection equipment works:

X-ray emission: After the 160kV ceramic X-ray tube built into glass x-ray tube inspection equipment is energized, electrons are accelerated by a high-voltage electric field to produce X-rays. X-rays have the characteristics of strong penetration and absorption by substances of different densities.

Difference between penetration and absorption: When X-rays penetrate the glass workpiece, the normal area inside the glass and the damaged area absorb X-rays to different degrees, causing differences in the intensity of X-rays after penetration.

Image imaging and recognition: X-rays with density difference information are received by the detector, converted into electrical signals, and processed by the intelligent analysis system to generate high-definition detection images. In the image, the hidden damage inside the glass will show a different grayscale or outline from the normal area. The staff can clearly identify the location, size and type of the damage through the image.

Specifications

Panoramic Portable X-ray Flaw Detector (with ceramic X-ray tube)

| Model | Output Voltage (kv) | Input (kw) | Focus (mm) | Beam Angle | Q235 Max. Penetration(mm) | Weight of Generator(kg) | Dimension of Generator(mm) | ||

| Cone Target | Flat Target | Cone Target | Flat Target | ||||||

| XXGH-2005 | 100~200 | 2.0 | 1.0×3.5 | 30×360° | 25×360° | 24 | 27 | 31 | 290×615 |

| XXGH-2505 | 150~250 | 2.5 | 1.0×2.4 | 30×360° | 25×360° | 34 | 37 | 35 | 325×705 |

| XXGH-3005 | 170~300 | 3.0 | 1.0×2.3 | 30×360° | 25×360° | 44 | 47 | 43 | 245×715 |

Panoramic Portable X-ray Flaw Detector (with glass X-ray tube)

| Model | Output Voltage (kV) | Input (kw) | Focus Size (mm) | Beam Angle | Q235 Max. Penetration(mm) | Weight of Generator(kg) | Dimension of Generator(mm) | ||

| Cone Target | Flat Target | Cone Target | Flat Target | ||||||

| XXH-1005 | 60~100 | 1.2 | 1.0×3.5 | 30×360° | 25×360° | 4 | 6 | 11.1 | 190×530 |

| XXH-1605 | 80~160 | 1.5 | 1.0×3.5 | 30×360° | 25×360° | 12 | 15 | 15 | 225×585 |

| XXH-2005 | 100~200 | 2.0 | 1.0×3.5 | 30×360° | 25×360° | 24 | 27 | 21.5 | 285×665 |

| XXH-2505 | 150~250 | 2.5 | 1.0×2.4 | 30×360° | 25×360° | 34 | 37 | 33.5 | 320×730 |

| XXH-3005 | 170~300 | 3.0 | 1.0×2.3 | 30×360° | 25×360° | 44 | 47 | 40 | 345×830 |

| XXH-3205 | 180~320 | 3.2 | 1.0×5.0 | 30×360° | 25×360° | 45 | 50 | 40 | 345×830 |

| XXH-3505 | 180~350 | 3.4 | 1.0×5.0 | 30×360° | 25×360° | 52 | 55 | 42.6 | 345×830 |

Directional Portable X-ray Flaw Detector (with glass X-ray tube)

| Model | Output Voltage (kV) | Input (kw) | Focus Size (mm) | Beam Angle | Q235 Max. Penetration(mm) | Weight of Generator(kg) | Dimension of Generator(mm) |

| XXQ-1005 | 60~100 | 1.2 | 0.8×0.8 | 40° | 8 | 11.1 | 190×530 |

| XXQ-1605 | 80~160 | 1.5 | 0.8×0.8 | 40° | 19 | 15.2 | 225×585 |

| XXQ-2050 | 100~200 | 2.0 | 1.5×1.5 | 40+5° | 30 | 23 | 285×665 |

| XXQ-2505 | 150~250 | 2.5 | 2.0×2.0 | 40+5° | 40 | 35 | 320×730 |

| XXQ-3005 | 170~300 | 3.0 | 2.3×2.3 | 40+5° | 50 | 45.5 | 345×830 |

| XXQ-3205 | 180~320 | 3.2 | 2.5×2.3 | 40+5° | 55 | 45.5 | 345×830 |

| XXQ-3505 | 180~350 | 3.4 | 2.8×3.0 | 40+5° | 60 | 47 | 345×800 |

Directional Portable X-ray Flaw Detector (with ceramic X-ray tube)

| Model | Output Voltage (kV) | Input (kw) | Focus Size (mm) | Beam Angle | Q235 Max. Penetration(mm) | Weight of Generator(kg) | Dimension of Generator(mm) |

| XXG-1605 | 80~160 | 1.5 | 0.8×0.8 | 40+5° | 19 | 14.5 | 225×550 |

| XXG-2005 | 100~200 | 2.0 | 2.0×2.0 | 40+5° | 30 | 18 | 285×615 |

| XXG-2505 | 150~250 | 2.5 | 2.0×2.0 | 40+5° | 40 | 30.5 | 320×640 |

| XXG-3005 | 170~300 | 3.0 | 2.5×2.5 | 40+5° | 50 | 36.5 | 345×670 |

| XXG-3505 | 180~350 | 3.5 | 2.5×2.5 | 40+5° | 60 | 38 | 345×670 |

Glass x-ray tube inspection equipment application:

Glass manufacturing industry: Glass X-ray tube inspection machine is used for quality inspection in the production process of flat glass, automotive glass, building safety glass, photovoltaic glass, etc., to investigate internal air bubbles, hidden cracks, impurity embedding and other defects generated in the production process, and to ensure the quality of the factory glass.

In the field of glass deep processing: Glass X-ray tube inspection machine detects the internal structural integrity of deep-processed products such as tempered glass, laminated glass, and bulletproof glass, such as residual stress cracks after tempering, and hidden layering of the intermediate layer of laminated glass, etc., to prevent unqualified products from flowing into the market.

Industrial equipment maintenance: Conduct regular inspections of the glass components on the equipment to identify fatigue cracks, corrosion damage, etc. after long-term use, and prevent equipment downtime or safety accidents caused by damage to glass components.

Our packaging:

We use high-density foam to customize the lining to fit the glass X-ray tube inspection machine fuselage and accessories, which can effectively buffer the vibration and shock during transportation and prevent damage to the glass X-ray tube inspection machine core components. The outer packaging is made of thickened waterproof cartons, and the interior is covered with moisture-proof film, which can cope with the humid environment during transportation and prevent the performance of glass X-ray tube inspection machine circuits and components from being affected by moisture.

Our guarantee:

We provide 24-hour online technical consulting services. Users who encounter operational problems or XXQ-1005 glass x-ray equipment failures can contact the technical team for guidance at any time. We can respond quickly and help customers solve problems. And provide users with free XXQ-1005 glass x-ray equipment usage videos to ensure that the user team can master XXQ-1005 glass x-ray equipment operations proficiently.

About us:

We are a high-tech enterprise focusing on the research and development, production and sales of non-destructive testing equipment. The core team has many years of experience in X-ray testing technology. Our XXQ-1005 glass x-ray equipment is not only popular in China, but also exported to overseas, and has won the trust of many customers. If you are interested in our XXQ-1005 glass x-ray equipment, please feel free to contact us!