For diameter 219mm~510mm X-ray pipeline welding inspection equipment

- Aolong

- China

- 15 days

- 1500pc/year

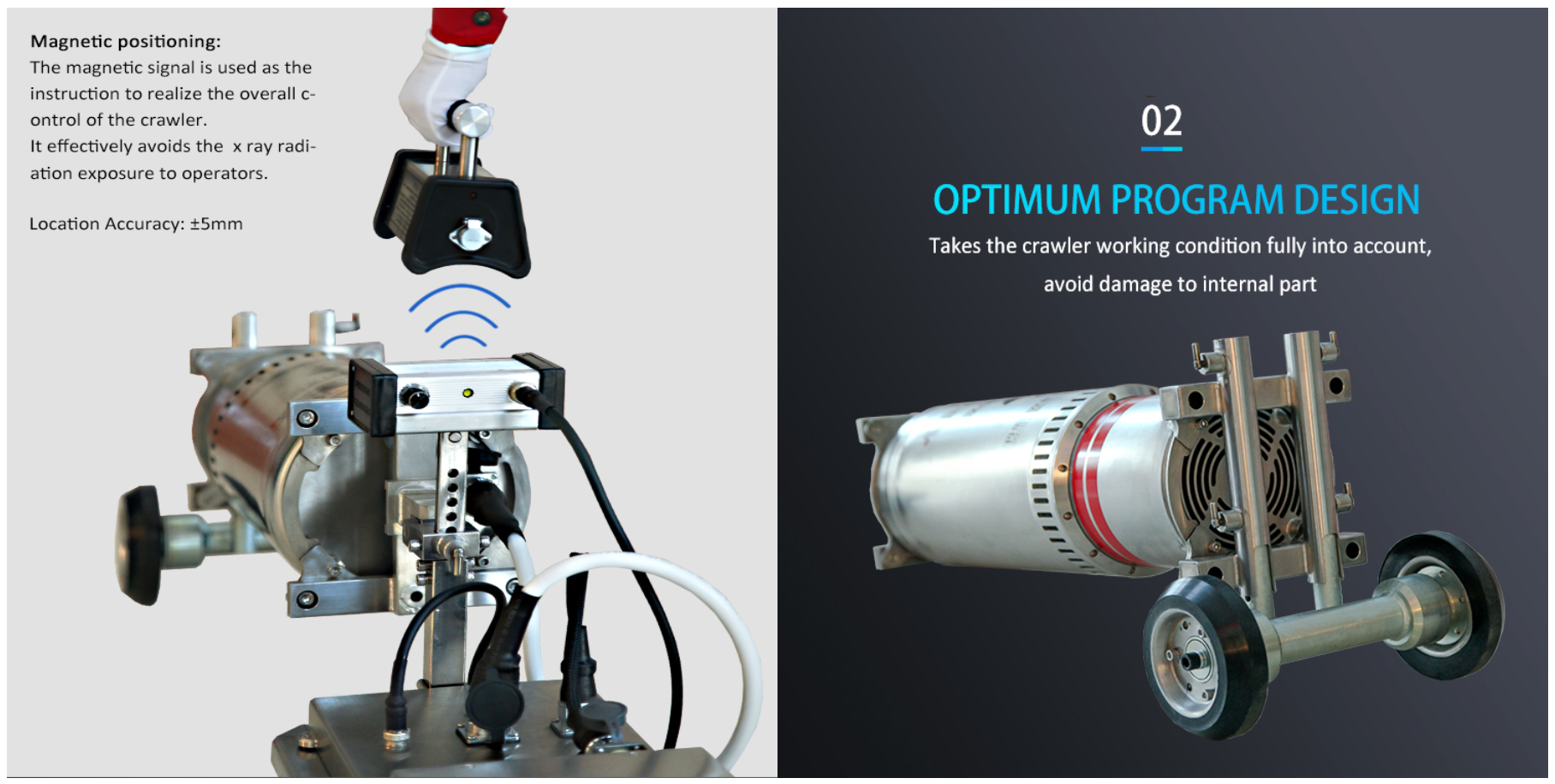

1. X-ray pipeline equipment utilizes advanced magnetic positioning technology, enabling safe and accurate inspections and improving efficiency.

2. X-Ray Pipeline Crawler can be customized to meet your specific inspection needs (e.g., special materials, higher precision).

3. X-Ray Pipeline Crawler features a PLC intelligent control system for convenient and fast use.

Product Description of X-ray welding inspection equipment:

X-ray welding inspection equipment is a compact, highly adaptable nondestructive testing solution suitable for pipe diameters ranging from 219mm to 510mm. Its optimized mechanical structure ensures smooth movement and precise positioning within this pipe diameter range, enabling clear, accurate X-ray imaging of girth welds. Utilizing advanced magnetic positioning technology, X-ray welding inspection equipment eliminates the safety risks and management burdens of traditional gamma-ray sources while delivering the same superior positioning accuracy and stability. X-ray pipeline equipment is suitable for pipeline welding in the oil and gas, long-distance water supply and drainage, and chemical industries.

Product Advantages of X-ray welding inspection equipment:

1. Pipeline welding inspection equipment utilizes advanced magnetic positioning technology, ensuring precise and reliable positioning.

2. Pipeline welding inspection equipment's compact design offers excellent crawling and obstacle-crossing capabilities, allowing it to navigate complex pipelines without hindrance.

3. X-ray pipeline equipment utilizes PLC intelligent control, enabling automatic crawling, positioning, and exposure, ensuring easy operation.

Applications of pipeline welding inspection equipment:

Whether it's steel pipes or other specialty alloy pipes, weld inspection is crucial to ensuring pipeline quality. Weld quality inspection is essential for natural gas and oil pipelines. Pipeline welding inspection equipment plays a vital role in weld inspection.

Features of pipeline welding inspection equipment:

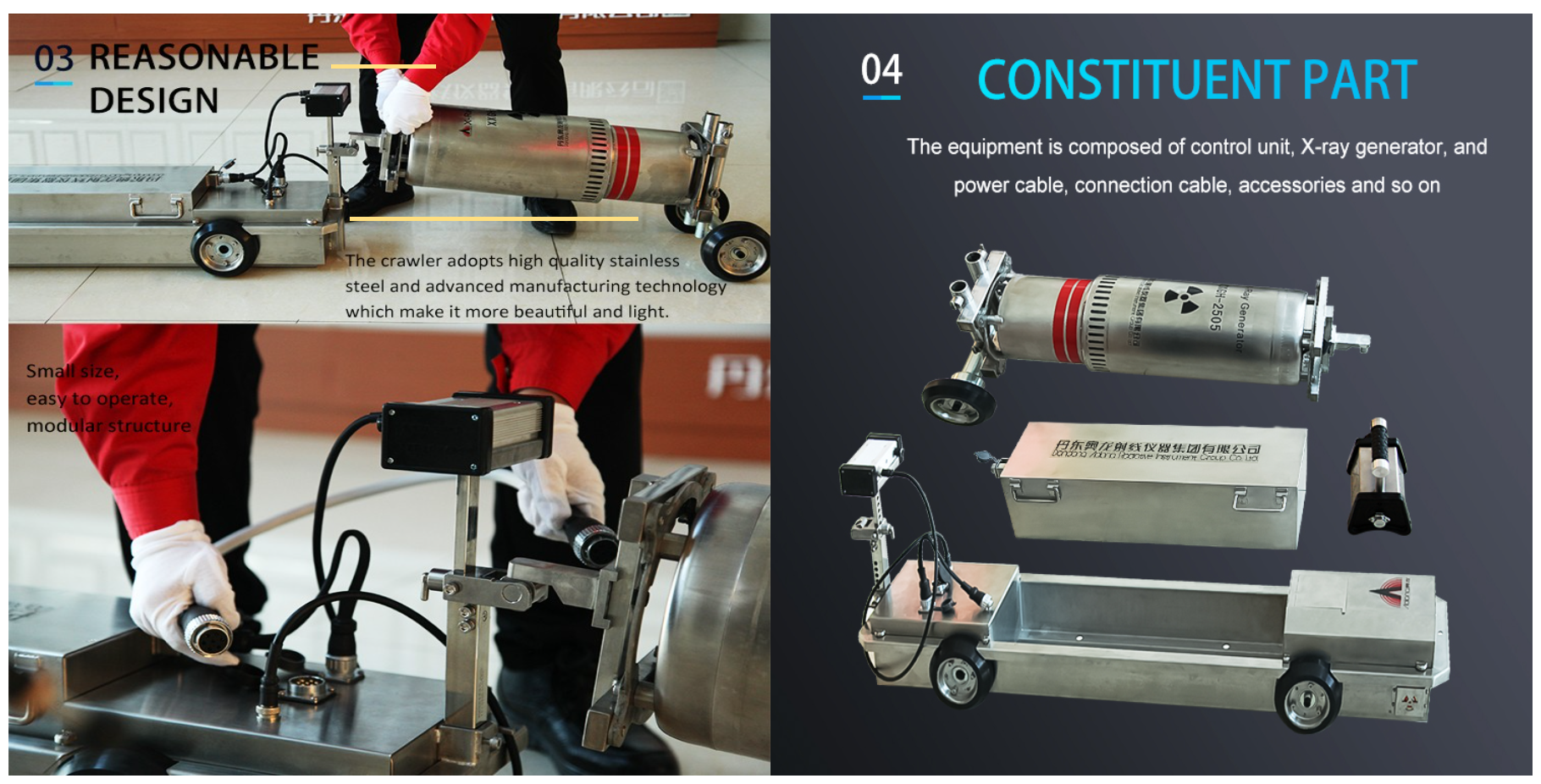

The X-Ray Pipeline Crawler is PLC-controlled and equipped with anti-jam and undervoltage protection, allowing it to be moved directly within the pipeline. The X-Ray Pipeline Crawler is easy to disassemble and assemble, making it highly portable. The operator can control X-ray parameters through external controls, allowing the X-Ray Pipeline Crawler to move, stop, and expose.

Technical Parameters of x-ray pipeline equipment:

| AL-100A | AL-100B | AL-100C | AL-100D | AL-100E | ||

| Item | Parameters | Parameters | Parameters | Parameters | Parameters | |

| Range of Pipe Diameter | φ810-1440mm | φ710-1219mm | φ410-1016mm | φ219-510mm | φ219-510mm | |

| Max.Penetration(A3 Steel) | 42mm | 35mm | 30mm | 24mm | 24mm | |

| Tube(Cone) | Max.Out Voltage | 350kv | 300kv | 250kv | 200kv | 200kv |

| Max.Out Current | 3mA | 3mA | 3mA | 3mA | 3mA | |

| Focal Size | 1.0×2.3mm | 1.0×3.5mm | 1.0×2.0mm | 1.0×2.0mm | 1.0×2.0mm | |

| Beam | 360°×30° | 360°×30° | 360°×30° | 360°×30° | 360°×30° | |

| Environment Temperature | -30°-80° | -30°-80° | -30°-80° | -30°-80° | -30°-80° | |

| Relative Humidity | ≤90% | ≤90% | ≤90% | ≤90% | ≤90% | |

| Energy Capacity of Battery | 120V,20Ah | 110V,22Ah | 106V,22Ah | 110V,10Ah | 96V,10Ah | |

| Crawling Ability | ≤45° | ≤45° | ≤45° | ≤45° | 30°-40° | |

| Location Accuracy | ±5mm | ±5mm | ±5mm | ±5mm | ±5mm | |

| Crawling Distance | 8Km(round trip) | 8Km(round trip) | 8Km(round trip) | 6Km(round trip) | 6Km(round trip) | |

| Crawling Speed | 16-18m/min | 16-18m/min | 16-18m/min | 16-18m/min | 16-18m/min | |

| Dimension (Crawler Vehicle) | 1400×400×219mm | 1250×270×180mm | 1200×300×190mm | 1180×230×160mm | 1600×140×140mm | |

| Tuming Radius | >70° | >70° | >70° | >70° | ≥10D | |

| Total Weight | 165Kg | 80Kg | 80Kg | 56.5Kg | 45Kg | |

Structure of x-ray pipeline equipment:

Crawler of pipeline welding inspection equipment:

1. The X-ray pipeline equipment's crawler utilizes electronic speed control technology, enabling slow start and low-speed positioning, ensuring more precise X-ray alignment at weld points.

2. Excellent performance, unaffected by welding machines.

3. Multiple real-time protection features protect x-ray pipeline equipment from water, overvoltage, overcurrent, and overheating.

4. The X-ray pipeline equipment features automatic battery level detection. If the battery is low, the crawler will return. If there is no signal, the crawler will also automatically return after 30 minutes.

Generator of X-ray welding inspection equipment:

1. X-Ray Pipeline Crawler's generator features constant voltage control, ensuring consistent X-ray density regardless of battery level. It also provides energy-saving and motor overcurrent protection.

2. X-Ray Pipeline Crawler's generator utilizes SF6 gas insulation, a grounded anode, and fan cooling.

3. The high-purity, high-density aluminum heat sink is designed specifically for our X-Ray Pipeline Crawler. Using high-temperature mounting technology, heat dissipation performance is improved by 30%.

4. The X-ray welding inspection equipment generator utilizes imported enameled high-voltage coils, significantly improving overall quality.

Batteries of X-Ray Pipeline Crawler:

Our X-Ray Pipeline Crawler utilizes panoramic lead-acid batteries. Compared to lithium batteries, our batteries offer 30% higher energy storage efficiency. Lead-acid batteries are also heat-resistant, effectively preventing overheating and explosion.

Our Qualifications:

Aolong Group's x-ray pipeline equipment, with its high resolution and intelligent features, has been designated a national key promotion project, demonstrating its leading position in digital testing. The company has also been awarded the title of "Liaoning Province Famous Trademark," further enhancing its brand influence in the industry and market. We also maintain a close partnership with GE to advance nondestructive testing technology toward international standards.

Factory Testing Services:

Aolong possesses comprehensive sample analysis capabilities for material performance and quality research. Through methods such as structural phase identification, stress change analysis, and quantitative analysis of non-standard samples, we can provide clients with in-depth insights into material properties. We are particularly experienced in microstructure measurement and performance evaluation of rolled plate, providing precise microstructure reports for various materials, including aluminum, iron, and copper. This analysis not only helps clients improve raw material selection and process optimization, but also ensures long-term product stability and service life from the source, providing a reliable basis for subsequent mass production.

Packing details of X-ray welding inspection equipment:

Each product will be packed in cartons or wooden cases (we also accept customers' demands)

Delivery time of x-ray pipeline equipment:

1. For sample order, 3-5 working days

2. For mass production, 5-7 weeks (It also depends on the order quantity and design)

About Us:

Aolong prioritizes customer experience, providing comprehensive services from prototype testing and solution design to equipment delivery and personnel training. We customize inspection processes based on the material, size, and defect characteristics of your parts to ensure accurate and efficient results. This integrated service process allows customers to quickly get started and achieve stable application. Aolong is not only an equipment supplier, but also a trusted testing solutions partner.