For diameter 410mm~1016mm Pipeline X-ray Inspection Equipment

- Aolong

- China

- 15 days

- 1500pc/year

1. NDT Industrial X-ray Pipeline inspection Crawler covers pipe diameters ranging from φ410mm to φ1016mm, meeting the weld inspection needs of common oil, gas, and industrial pipelines.

2. NDT Industrial X-ray Pipeline inspection Crawler has a single return inspection range of up to 8 km (round trip), making it ideal for long-distance pipeline inspections and continuous operations.

3. X-ray Pipeline Crawler automatically detects battery charge and returns promptly when the battery voltage is low.

Product Introduction of NDT Crawler for Testing Pipeline Detector:

NDT Crawler for Testing Pipeline Detector is a professional inspection device launched by Aolong for nondestructive testing (NDT) of medium- and large-sized pipeline welds. It is used for inspecting welds and pipe bodies of oil, gas, and other pipelines transporting movable materials. NDT Crawler for Testing Pipeline Detector uses a battery-powered, mobile, and portable X-ray source to perform high-resolution imaging of the pipeline's circumference and wall. Suitable for on-site, internal inspection, or emergency inspections, X-ray Pipeline Crawler automatically monitors power levels and retracts in complex environments, ensuring inspection continuity and operational safety. It is highly practical in complex and narrow pipelines.

Main Function:

● The X-ray Pipeline Crawler can inspect the power of the battery automatically. When the battery voltage is low, it will return in time.

● Constant current control ensures the film's coherence.

● High precision of tube voltage adjustment ensures the film's coherence.

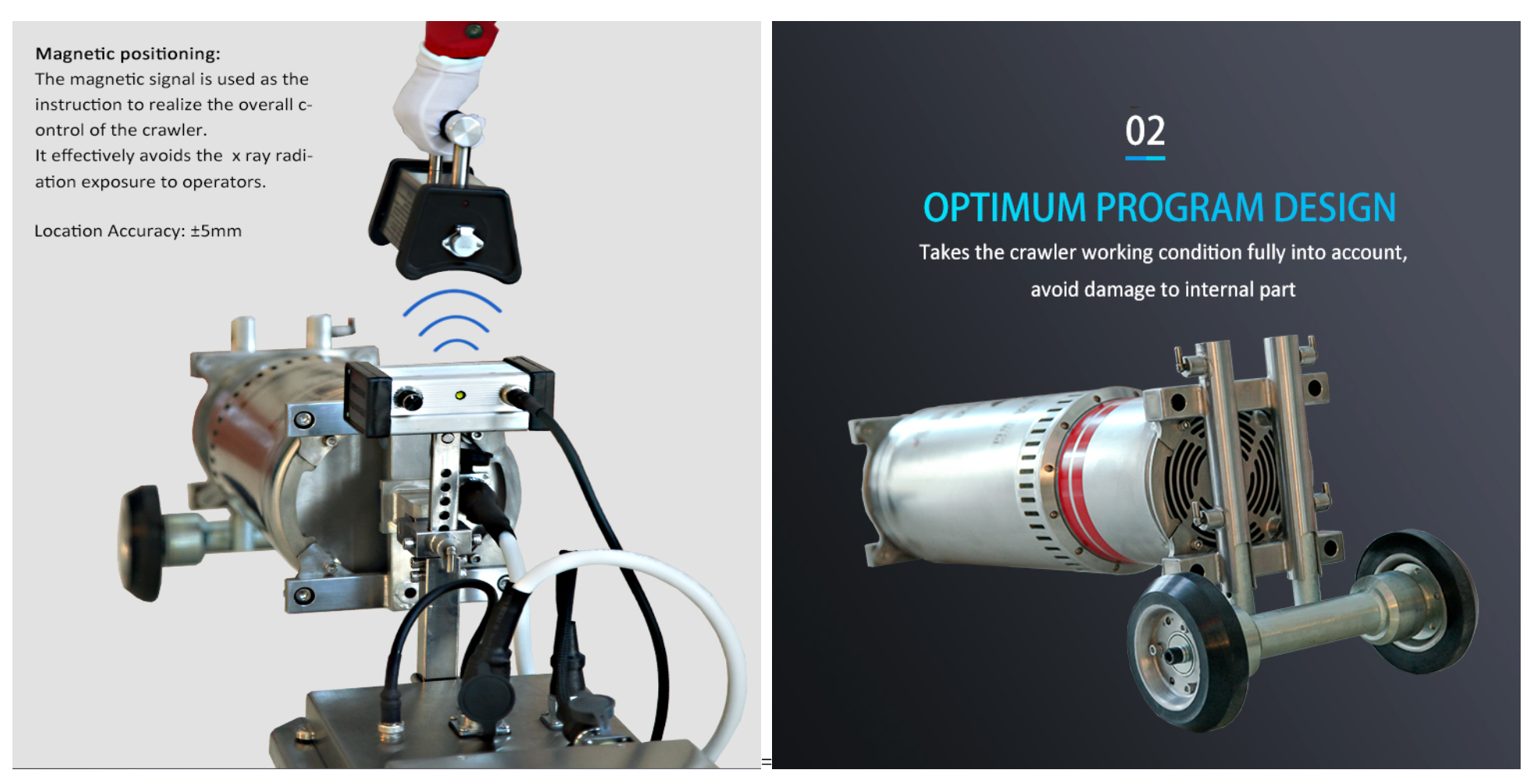

● There are all kinds of real time protection functions, such asmeeting water,over-voltage, zero voltage, over current, zerovoltage, inspection for battery voltage, barrier, antenna falling off, X-ray generator falling off, over heat of the X-ray generator, receive failure, motor over power, parameters setting failure, demosetting failure ensures that the pipeline inspection Crawler can work properly in complex environment.

● Optimum program design takes the crawler's working condition fully into account, avoiding damage to the internal parts.

Technical Parameters:

| AL-100A | AL-100B | AL-100C | AL-100D | AL-100E | ||

| Item | Parameters | Parameters | Parameters | Parameters | Parameters | |

| Range of Pipe Diameter | φ810-1440mm | φ710-1219mm | φ410-1016mm | φ219-510mm | φ219-510mm | |

| Max.Penetration(A3 Steel) | 42mm | 35mm | 30mm | 24mm | 24mm | |

| Tube(Cone) | Max.Out Voltage | 350kv | 300kv | 250kv | 200kv | 200kv |

| Max.Out Current | 3mA | 3mA | 3mA | 3mA | 3mA | |

| Focal Size | 1.0×2.3mm | 1.0×3.5mm | 1.0×2.0mm | 1.0×2.0mm | 1.0×2.0mm | |

| Beam | 360°×30° | 360°×30° | 360°×30° | 360°×30° | 360°×30° | |

| Environment Temperature | ‘-30°-80° | ‘-30°-80° | ‘-30°-80° | ‘-30°-80° | ‘-30°-80° | |

| Relative Humidity | ≤90% | ≤90% | ≤90% | ≤90% | ≤90% | |

| Energy Capacity of Battery | 120V,20Ah | 110V,22Ah | 106V,22Ah | 110V,10Ah | 96V,10Ah | |

| Crawling Ability | ≤45° | ≤45° | ≤45° | ≤45° | 30°-40° | |

| Location Accuracy | ±5mm | ±5mm | ±5mm | ±5mm | ±5mm | |

| Crawling Distance | 8Km(round trip) | 8Km(round trip) | 8Km(round trip) | 6Km(round trip) | 6Km(round trip) | |

| Crawling Speed | 16-18m/min | 16-18m/min | 16-18m/min | 16-18m/min | 16-18m/min | |

| Dimension (Crawler Vehicle) | 1400×400×219mm | 1250×270×180mm | 1200×300×190mm | 1180×230×160mm | 1600×140×140mm | |

| Tuming Radius | >70° | >70° | >70° | >70° | ≥10D | |

| Total Weight | 165Kg | 80Kg | 80Kg | 56.5Kg | 45Kg | |

Product Advantages of X-ray Pipeline Crawler:

Aolong's X-ray Pipeline Crawler is specifically designed for pipeline inspection. Its structure, drive, and power systems are optimized for crawling inside and outside pipes. It features automatic power monitoring and low-battery return-to-home, effectively reducing on-site operational risks and repair costs. Equipped with a 250 kV high-energy X-ray source and 30 mm steel penetration, the X-ray Pipeline Crawler easily handles inspections of thick-walled pipes and complex welds, eliminating the need for frequent equipment replacements. The X-ray Pipeline Crawler also boasts excellent environmental adaptability, operating stably in temperatures ranging from -30°C to 80°C and humidity levels ≤90%, making it suitable for a variety of complex field conditions and demonstrating exceptional reliability and durability.

Reasonable Design of X-ray Pipeline Crawler:

The X-ray Pipeline Crawler is designed with practicality and durability in mind. Constructed from high-quality stainless steel and utilizing advanced manufacturing techniques, it boasts an attractive appearance and robust structure, ensuring long-term, stable operation in high-intensity operating environments. Its compact size and moderate weight make it easy to carry and deploy, making it particularly suitable for inspections in the field or confined spaces. The modular design of the X-ray Pipeline Crawler facilitates quick assembly and disassembly, as well as maintenance, reducing on-site operational complexity. It supports a variety of component replacements and functional expansions to accommodate varying pipe diameters and inspection requirements.

Application Scenarios of NDT Industrial X-ray Pipeline inspection Crawler:

Pipeline Weld and Butt Weld Inspection: The NDT Industrial X-ray Pipeline inspection Crawler can move steadily along the inside or outside of the pipeline, combining circumferential or oblique X-ray exposure to image the butt and longitudinal seams. This allows for identification of defects such as lack of fusion, cracks, slag inclusions, and shrinkage cavities. It supports rapid on-site image analysis and post-processing.

Daily Inspection and Emergency Inspection of Oil and Gas Pipelines: During pipeline maintenance, the NDT Industrial X-ray Pipeline inspection Crawler is used to quickly assess weld integrity and pipe wall damage during regular inspections or after incidents. Its long travel range and automatic return function reduce the risk and workload of manual reentry.

On-site Construction Quality Inspection: After the installation of new or overhauled pipeline sections, the NDT Crawler for Testing Pipeline Detector can be used to perform spot or full inspections of each weld, providing traceable records of construction quality and reducing rework and potential risks.

Inspecting Complex Environments Such as Cold, Hot, and Humid: The NDT Crawler for Testing Pipeline Detector has a wide operating temperature range (-30°C to 80°C) and excellent moisture resistance, making it suitable for inspections in extreme environments such as islands, northern oil fields, and coastal pipelines.

Emergency repair and third-party non-destructive testing services: Third-party testing agencies or repair teams can carry NDT Crawler for Testing Pipeline Detector for rapid deployment and provide customers with rapid imaging reports and defect location services based on convenient crawling and filming capabilities.

Packing details:

Each product will be packed in cartons or wooden cases (we also accept customers' demands)

Delivery time:

1. For sample order, 3-5 working days

2. For mass production, 5-7 weeks (It also depends on the order quantity and design)

Honors and Qualifications:

Several of the company's products have been designated as National Key New Products, demonstrating that Aolong's R&D achievements in industrial nondestructive testing equipment have reached advanced domestic standards. X-ray Pipeline Crawler has achieved significant breakthroughs in resolution, real-time imaging, and intelligence, and is widely used in various pipeline inspection applications. This honor not only fuels the company's rapid growth but also demonstrates Aolong's ability to continuously innovate and commercialize, providing customers with higher-value inspection solutions.

About us:

Aolong Group is a high-tech private enterprise with more than 50 years history and has powerful comprehensive technology strength. Aolong Group is not only the professional developer and manufacturer for radiograpny equipment and material testing instrument, but also the supplier of the application solution for the inspecting instrument.