For diameter 810mm~1440mm X-ray Pipeline Inspection Crawler

- Aolong

- China

- 15 days

- 1500pc/year

1. X-Ray Pipeline Crawler uses a Siemens S7-200 PLC as its control system, ensuring high reliability and stability.

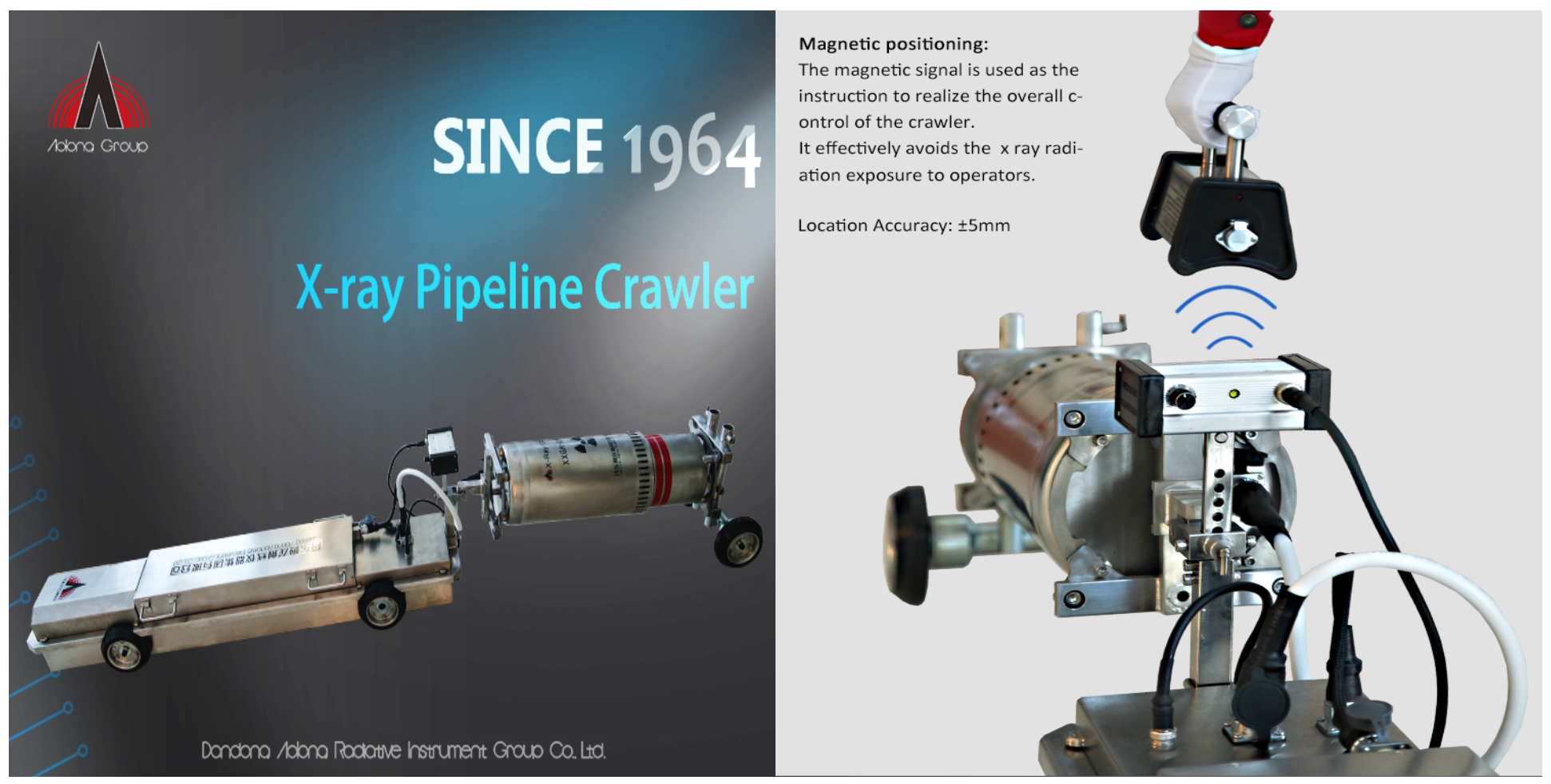

2. X-Ray Pipeline Crawler is equipped with an advanced magnetic positioning system, ensuring high precision and sensitivity during the detection process.

3. X-Ray Pipeline Crawler offers massive storage capabilities and robust security and confidentiality.

Product Description of X-Ray Pipeline Crawler:

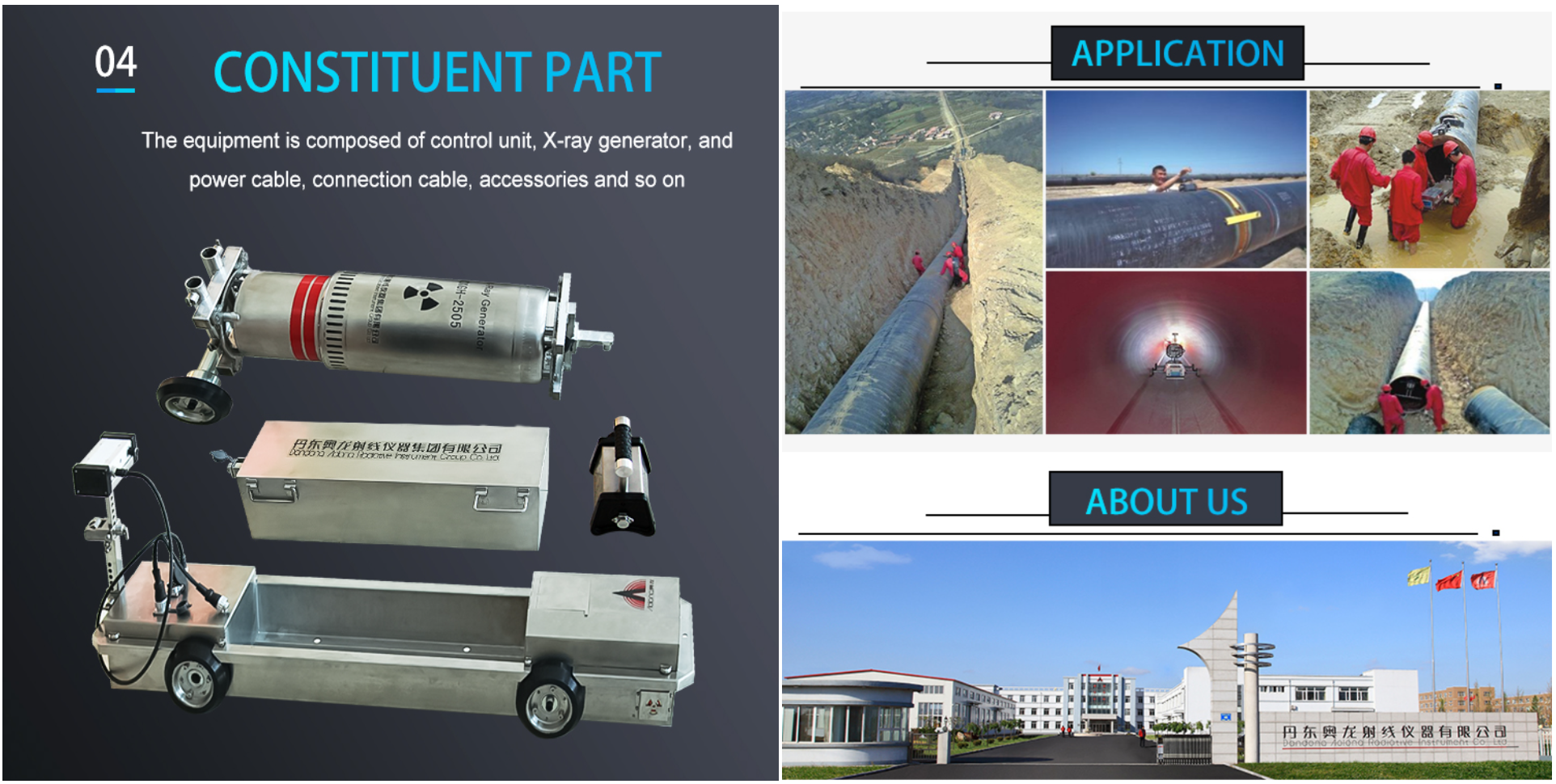

The X-Ray Pipeline Crawler is an X-ray pipeline inspection crawler suitable for pipelines with diameters ranging from 810mm to 1440mm. It is a high-precision inspection device designed specifically for nondestructive testing (NDT) of large-diameter pipeline welds. Equipped with core systems including X-ray source control, power management, automatic navigation, image acquisition, and wireless communication, the X-Ray Pipeline Crawler enables autonomous navigation, precise positioning, and inspection within closed pipelines. Its air-grade stainless steel housing and modular design are waterproof, shockproof, and corrosion-resistant, making it suitable for complex construction environments such as those in the oil and gas, water conservancy, and chemical industries, and it can effectively perform inspection tasks within pipelines. The Pipeline X-ray Inspection crawler also features automatic return-to-home, low-battery notification, and intelligent exposure adjustment, making it quick and easy to use.

Working Principle of Pipeline X-ray Inspection Equipment:

The Pipeline X-ray Inspection crawler is an automated X-ray generator, powered by mechanical components, that autonomously crawls inside the pipeline carrying the X-ray generator.

Outside the pipeline, the operator pre-places specialized X-ray film and identification tags at the butt girth welds to be inspected.

A remote control device located outside the pipeline precisely directs the Pipeline X-ray Inspection crawler inside the pipeline and performs X-ray exposure at the designated location.

Finally, the Pipeline X-ray Inspection crawler uses X-rays to penetrate and photograph the pipeline's butt girth welds, enabling high-quality nondestructive testing.

Technical Parameters of Pipeline X-ray Inspection Equipment:

| AL-100A | AL-100B | AL-100C | AL-100D | AL-100E | ||

| Item | Parameters | Parameters | Parameters | Parameters | Parameters | |

| Range of Pipe Diameter | φ810-1440mm | φ710-1219mm | φ410-1016mm | φ219-510mm | φ219-510mm | |

| Max.Penetration(A3 Steel) | 42mm | 35mm | 30mm | 24mm | 24mm | |

| Tube(Cone) | Max.Out Voltage | 350kv | 300kv | 250kv | 200kv | 200kv |

| Max.Out Current | 3mA | 3mA | 3mA | 3mA | 3mA | |

| Focal Size | 1.0×2.3mm | 1.0×3.5mm | 1.0×2.0mm | 1.0×2.0mm | 1.0×2.0mm | |

| Beam | 360°×30° | 360°×30° | 360°×30° | 360°×30° | 360°×30° | |

| Environment Temperature | ‘-30°-80° | ‘-30°-80° | ‘-30°-80° | ‘-30°-80° | ‘-30°-80° | |

| Relative Humidity | ≤90% | ≤90% | ≤90% | ≤90% | ≤90% | |

| Energy Capacity of Battery | 120V,20Ah | 110V,22Ah | 106V,22Ah | 110V,10Ah | 96V,10Ah | |

| Crawling Ability | ≤45° | ≤45° | ≤45° | ≤45° | 30°-40° | |

| Location Accuracy | ±5mm | ±5mm | ±5mm | ±5mm | ±5mm | |

| Crawling Distance | 8Km(round trip) | 8Km(round trip) | 8Km(round trip) | 6Km(round trip) | 6Km(round trip) | |

| Crawling Speed | 16-18m/min | 16-18m/min | 16-18m/min | 16-18m/min | 16-18m/min | |

| Dimension (Crawler Vehicle) | 1400×400×219mm | 1250×270×180mm | 1200×300×190mm | 1180×230×160mm | 1600×140×140mm | |

| Tuming Radius | >70° | >70° | >70° | >70° | ≥10D | |

| Total Weight | 165Kg | 80Kg | 80Kg | 56.5Kg | 45Kg | |

Advantages of 810 mm xray Pipeline Inspection machine:

1. 810 mm xray Pipeline Inspection machine employs a digital control system with real-time adjustable exposure parameters for clearer and more accurate weld imaging.

2. Automatic positioning, auto-return navigation, and low-battery alerts minimize manual intervention and enhance safety.

3. Featuring a stainless steel housing, 810 mm xray Pipeline Inspection machine is waterproof and dustproof, making it ideal for pipeline applications.

4. Equipped with a high-capacity lithium battery system, Pipeline X-ray Inspection Equipment enables extended continuous inspection.

FAQs of Pipeline X-ray Inspection Equipment:

Q: How does 810 mm xray Pipeline Inspection machine perform inspections? Does it require excavation of the pipeline?

A: No, it doesn't require full excavation. 810 mm xray Pipeline Inspection machine crawls inside the pipeline and completes the exposure.

Q: What are the advantages of magnetic positioning technology over traditional gamma-ray sources?

A: Pipeline X-ray Inspection Equipment's core advantages lie in safety and environmental protection. It completely eliminates the radiation hazards of gamma-ray sources, eliminating the need for complex radiation source licenses. It is also simpler to operate, significantly reducing personnel burden and safety risks.

Q: What is the accuracy and reliability of Pipeline X-ray Inspection Equipment's inspections?

A: Pipeline X-ray Inspection crawler's advanced magnetic positioning system achieves positioning accuracy and stability similar to that of a gamma-ray source, ensuring clear images and accurate positioning, fully meeting the non-destructive testing requirements of various industrial standards.

Q: What types of pipelines are suitable for Pipeline X-ray Inspection crawler?

A: Pipeline X-ray Inspection Equipment is widely applicable to industrial pipelines of various materials and uses, including oil and gas, municipal water supply and drainage, chemical, electric power, and nuclear power. It is particularly advantageous in long-distance transmission pipelines.

Q: Is X-Ray Pipeline Crawler complicated to operate? What are the operator requirements?

A: X-Ray Pipeline Crawler is highly automated and intuitively operated via external remote control. However, operators must possess professional NDT qualifications and receive specialized training on this equipment to ensure standardized testing procedures and accurate interpretation of results.

As a trusted partner, Aolong's service and support programs prioritize productivity. Through a comprehensive support system, we help customers extend the lifecycle of their X-Ray Pipeline Crawlers, reduce losses from unexpected downtime, and achieve a higher return on investment. Our limited warranty and 24/7 telephone support provide customers with solid technical support, ensuring that problems can be resolved promptly at any time.

Packing details of X-Ray Pipeline Crawler

Each product will be packed in cartons or wooden cases (we also accept customers' demands)

Delivery time

1. For sample order, 3-5 working days

2. For mass production, 5-7 weeks (It also depends on the order quantity and design)

Honors:

Aolong has partnered with the Chinese Academy of Sciences to establish an Academician Expert Workstation, providing high-level academic support for the company's R&D. This team of academicians participates in key technology reviews and R&D, improving the efficiency of research and development. This helps the company achieve continuous breakthroughs in high-resolution detectors, intelligent algorithms, and industrial CT technology, maintaining its industry-leading position. This honor demonstrates the company's strategic focus on scientific and technological innovation and is a key factor in enhancing product competitiveness.

About us:

Since its founding, Aolong Group has been deeply engaged in the fields of nondestructive testing and materials testing. We not only possess comprehensive corporate management systems and a modern production environment, but also have established academician expert workstations and a postdoctoral research base, forming a robust research and innovation system. Our main products include Pipeline X-ray Inspection crawler, 810 mm xray Pipeline Inspection machine, X-Ray Pipeline Crawler, and other nondestructive testing equipment.