X-ray micro focus CT industrial NDT inspection System

- Aolong

- China

- 15 days

- 80pc/year

1. The micro nondestructive testing ct system utilizes a microfocus X-ray source and a high-resolution detector, resulting in a compact size while offering a very wide range of inspection capabilities.

2. The micro nondestructive testing ct system supports high-resolution radiography and high-speed CT scanning, with simple operation.

3. The Industrial X-ray System can be paired with 160kV–300kV microfocus X-ray sources, achieving a JIMA resolution of up to 0.5 μm.

Product introduction of Industrial X-ray System:

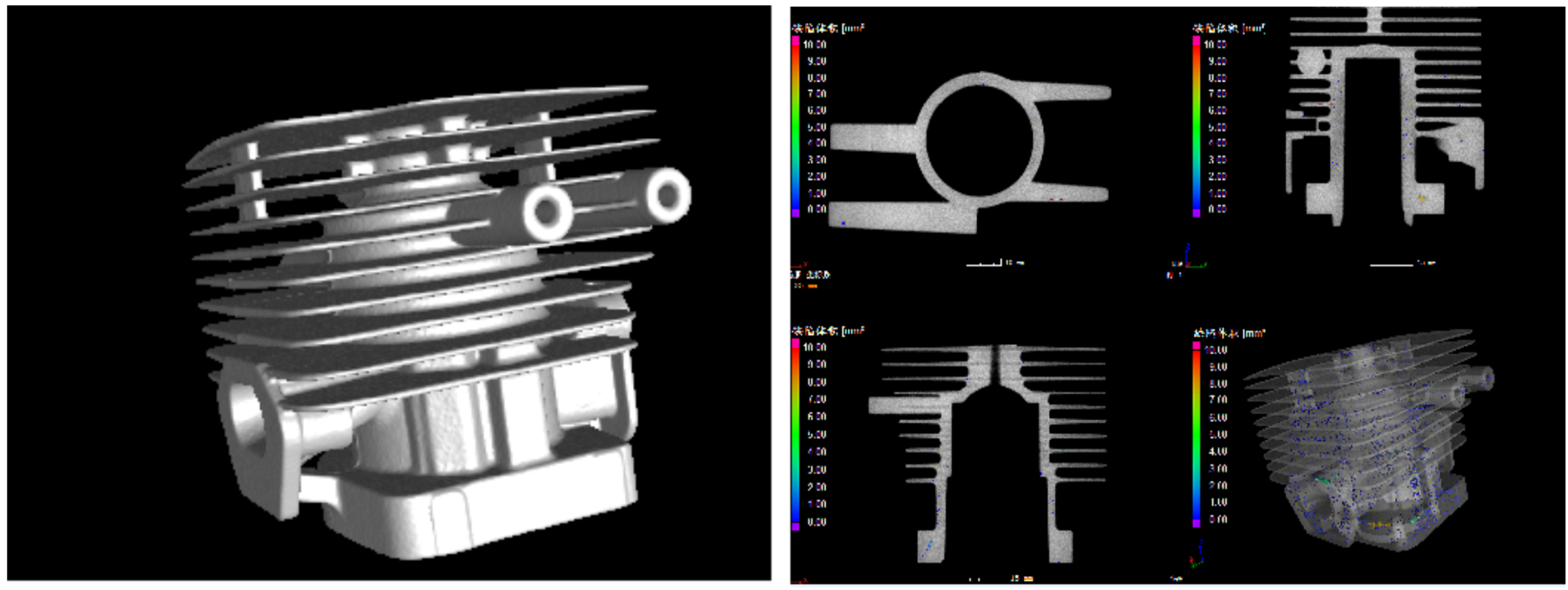

X-ray micro focus CT inspection System is ideal for inspecting metal,ceramics, core, complex casting part and semiconductor. X-ray micro focus CT inspection System is widely used in aerospace, machinery, electric, material, geology, archaeology fields and others. X-ray micro focus CT inspection System allows you to see the inside of something without having to destroy the object itself. What we typically think of as X-ray vision is similar to planar X-ray images that you get in a hospital when you break an arm. Micro CT is more like the medical CT systems where you get slice-by-slice information, but without having to cut up the sample. With X-ray micro focus CT inspection System you can see what is in an object, while with 3D X-ray systems, such as the Micro CT, you can see where those things are located. This is useful for nondestructively visualizing and analyzing the internal structure of materials (composites, metals, bones, soft tissues, geological cores, manufacture objections, etc).

Main Functions of micro focus ct inspection system:

● Open target micro-focus X-ray tube of long working life and the stableper formance.

● The Industrial ndt inspection system is 3D volume CT.

● Stable marble base ensure the equipment's stability.

● High precision bearing technique and linear slideway system ensure the high precision measurement.

● Compact appearance design with the small cabinet required.

● The Industrial X-ray System can Automatic fast inspecting, analyzing, and displaying internal defect and pore.

● Analyzing each defect's volume, position, size and surface area.

● Industrial X-ray Systems with marking different volume defect in different color.

● Industrial ndt inspection system can Analyze and count the whole object or ROl area,analyze defect size,total pore ratio and pore volume.

● Analysis result can be printed and saved.

Product Advantages of Industrial X-ray System:

Industrial X-ray System can output very clear microstructural images, and its intelligent scanning architecture allows for the acquisition of high-quality data in a short time, without sacrificing efficiency or image quality. Industrial X-ray System has a simple structure, low operating threshold, and low maintenance costs, making it well-suited for both small-batch precision inspection and large-scale online inspection.

Application Areas

Micro nondestructive testing ct system is suitable for various industrial scenarios requiring in-depth observation of internal structures, such as precision castings, electronic packaging, complex assemblies, additive manufacturing (metal 3D printing) parts, lithium battery components, and aerospace components. Whether verifying product consistency, analyzing defect locations and sizes, or performing rapid sampling during the production process, micro nondestructive testing ct system provides intuitive and reliable three-dimensional inspection results, making it a very practical tool for quality control and R&D analysis.

Company Honors:

Aolong Group has been awarded the National-Level Industrialization Demonstration Engineering Center for its achievements in the aerospace, defense, and automotive sectors. This honor fully affirms the company's outstanding contributions to high-end manufacturing. The company's products are widely used in the testing tasks of the "Shenzhou series spacecraft," demonstrating its top-tier technical capabilities. At the same time, as a well-known software company in Liaoning Province, we also possess strong advantages in testing software development and system integration. These honors and qualifications bear witness to Aolong's comprehensive transformation from a manufacturing-oriented enterprise to an innovation-driven enterprise.

About Us:

Aolong Group focuses on collaboration between industry, academia, and research institutions. We have established partnerships with the Chinese Academy of Sciences, Tsinghua University, and numerous other universities to jointly tackle key technologies. Through research projects and talent development, the company continuously transforms cutting-edge achievements into commercial products. The establishment of an academician and expert workstation and a postdoctoral research station provides Aolong with a strong scientific research support system, enabling us to maintain technological leadership in the industry and guide future development.