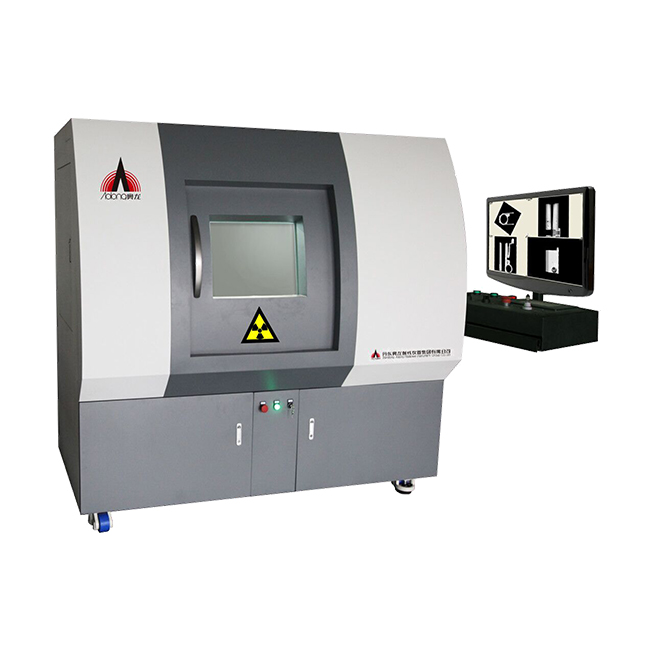

Industrial Computer Tomography CT Radiography System

- Aolong

- China

- 15 days

- 80pc/year

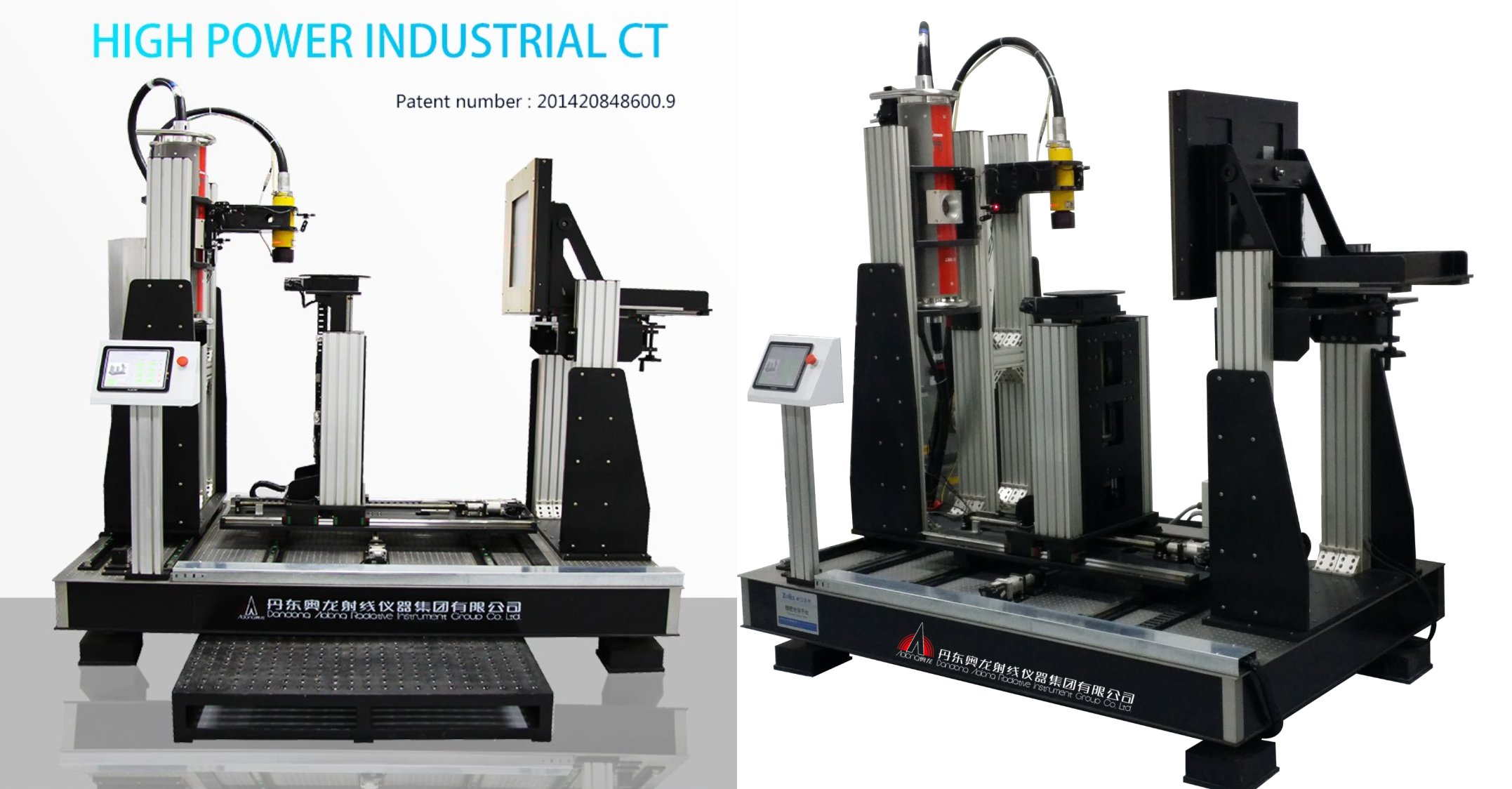

1. Using High Energy Industrial CT Scanner, you can directly view three-dimensional internal details; even micron-sized defects cannot be hidden.

2. High power Industrial CT can inspect metals, plastics, ceramics, electronic components, and more; one system handles multiple product types.

3. High Energy Industrial CT Scanner automatically reconstructs 3D models and analyzes defects, providing highly reliable data.

Product introduction of Industrial computer tomography system:

Industrial Computed Tomography CT is a 3D imaging system specifically designed for inspecting industrial components. It can completely reconstruct internal structures invisible to the naked eye. Whether it's complex metal parts, lightweight materials, or electronic modules, Industrial Computed Tomography CT can clearly scan them into 3D models. The entire Industrial Computed Tomography CT system is designed to be smarter and more automated, making operation as simple as using ordinary testing equipment, yet providing very detailed internal structural information. It's a highly practical piece of equipment for modern non-destructive testing.

Product Advantages of Industrial computer tomography system:

Industrial computer tomography system not only boasts high resolution, capable of detecting even micron-sized pores, voids, and cracks, but also offers fast scanning speeds, saving considerable inspection time. The system's software is also powerful, automatically reconstructing 3D images and performing slice analysis and thickness measurements on complex structures, providing more useful data for engineering and R&D teams. high power Industrial CT supports the inspection of various materials, requiring minimal adjustments when switching between batches or products, and exhibiting excellent stability, making it suitable for long-term use in high-intensity production lines.

Main Functions of Industrial computer tomography system:

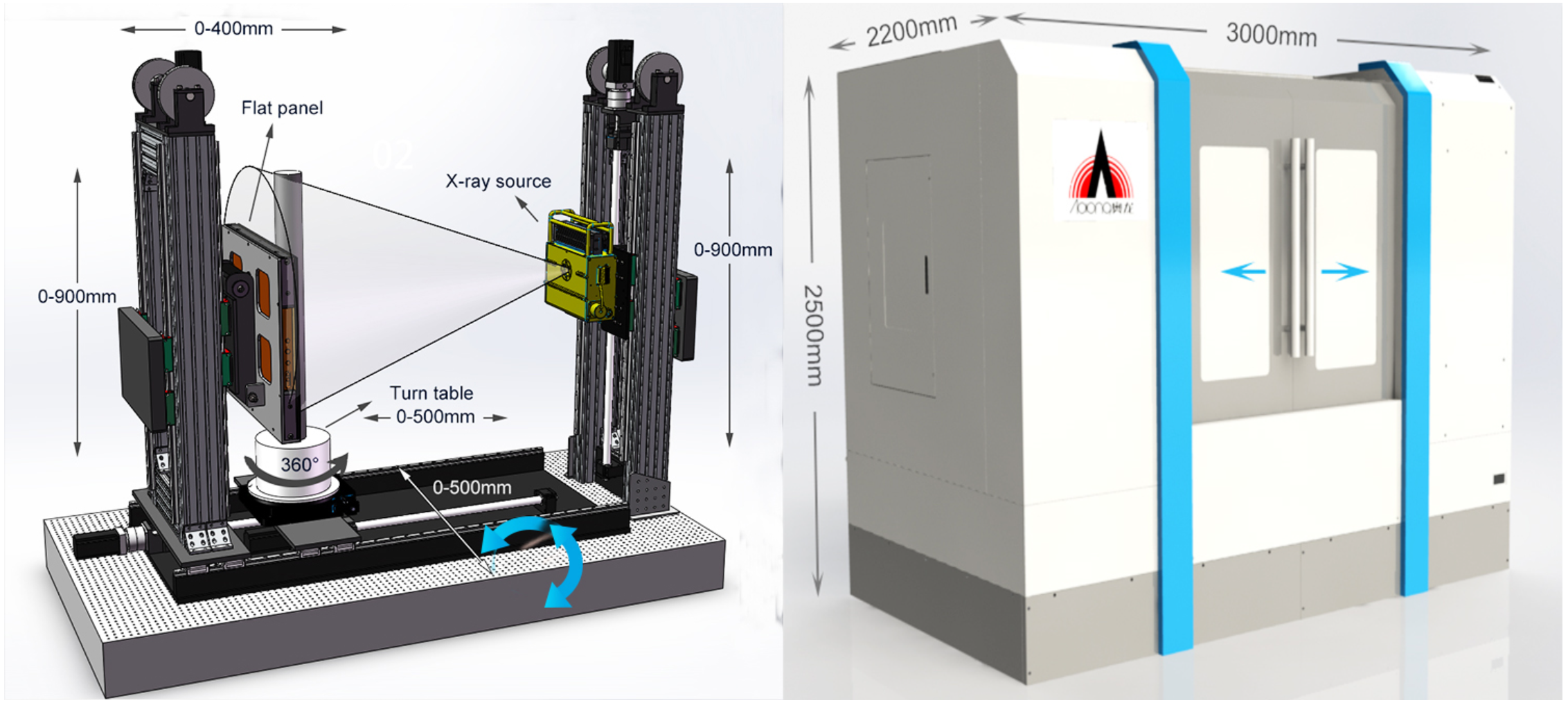

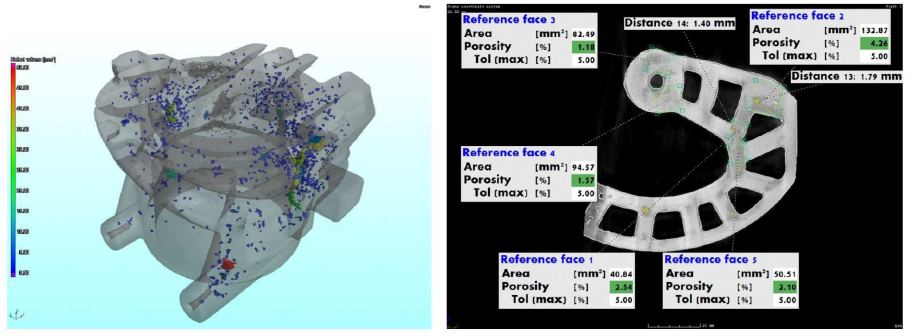

● Using cone beam CT scan and DR inspection mode,based on the measurement of the object, Industrial computer tomography system can get thousands pieces tomographic.images at one time .

● The Industrial Computed Tomography CT with the highest possible flexibility for individual customer requirements.

● The High Energy Industrial CT Scanner can analyze defects and pores to support ROl scan.

● Mark the defect's volume, size, and position with a different color.

● Analysis of wall thickness: mark the analysis results in a different color.

● Measure the position, distance, radius, angle, and other parameters of the object.

● Reverse engineering by CAD design compared with the physical object.

● Segmentation tool: data centralization, segmentation according to material and geometry.

● Achieve accurate measurement of internal dimensions of the object.

High Energy Industrial CT Scanner has the advantages such as compact, high speed inspection, high resolution images, accurate inspection and high ratio of performance to price.

Main Parameters of high power Industrial CT:

| Tube voltage | 20kV~450kV |

| Focus size | 0.4mm |

| Density resolution | 0.50% |

| Scan mode | cone bean scan |

| Detector | digital flat detector or linear detector |

Inspection Samples of Industrial Computed Tomography CT:

Whether it's for automotive parts inspection, complex aerospace structure evaluation, or electronic product solder joint inspection, high power Industrial CT is generally applicable. high power Industrial CT is particularly suitable for products with complex internal structures that cannot be disassembled for inspection, such as die-cast parts, composite materials, ceramic components, battery packs, and semiconductor devices. Many companies also use high power Industrial CT as a powerful R&D tool to verify the reliability of new materials and processes, or for rapid sampling inspection on production lines to ensure consistent quality.

Honors and Qualifications:

Aolong Group has established a postdoctoral research station and has been approved as a corporate postdoctoral research base. This platform has attracted numerous high-level research talents, promoting cutting-edge research and its practical application. Through collaborations with universities and research institutions, we continuously innovate in areas such as novel radiation sources, detectors, and artificial intelligence algorithms. This qualification not only enhances the company's research capabilities but also cultivates and reserves professional talents for the industry, strengthening the company's long-term development momentum.

About us:

Aolong has a global network of agents and service centers, and its products are exported to more than 60 countries and regions across five continents. The company has established a comprehensive overseas service system, providing customers with installation, commissioning, training, and after-sales support. This localized service model shortens equipment delivery and operation cycles, enhancing the customer experience. With its reliable products and efficient services, Aolong has gradually gained widespread recognition and trust in the international market.